An engine is any machine that converts any type of energy into mechanical energy. According to this definition some types of engines exist. They are:

- Air engines;

- Water engines;

- Electric engines;

- Thermal engines;

- Nuclear engines.

Since your creation, automobiles are powered by thermal or electric engines. Although the thermal engines are most used for cars than the electric engines, these evolved and reached levels of technology needed for large scale automotive application. However, this article only will approach the thermal engines.

From thermal engines, two types are most used in general industry, they are:

- Steam engines;

- Internal combustion engines.

Steam engines was used on first cars and prototypes, your major feature are the production of power from a external combustion. The combustion are realized out of the engine and makes it big enough to harm the performance of the car. Then, steam engines was surpassed by internal combustion engines.

Internal Combustion Engine

The operation began when the piston moves from the upper extremity to the lower extremity of the cylinder, that move creates a negative pressure that sucks the air to inside the cylinder. These extremities are known by top dead center(TDC) and bottom dead center(BDC) respectively.

The sucked air are piped to cylinder by the intake manifold, that air are mixed with pulverized fuel forming air/fuel mixture (port fuel injection configuration). The air/fuel mixture inlet and combustion gases exit are possible owing the intake and exhaust valves respectively. They are activated by the camshaft, and this makes the intake and exhaust valves open and close. Gears are bolted on camshafts and crankshaft, and they are synchronized by a rubber or metallic belt.

The mixture combustion occurs over pressure, takes place subsequent time meanwhile engines still working. The compression of mixture are realized by the piston when it move to TDC. As a result, a great rise of temperature and pressure inside the combustion chamber occurs. A spark plug produced spark initiate the combustion of mixture that pull the piston to BDC. This movement is transmitted to a rod, that are connected to the piston and the crankshaft. The action of rod over the crankshaft converts linear motion from the rod in rotary motion from crankshaft. The combustion gases are piped to exhaust system.

The crankshaft rotates over bearings and is covered by the carter, an aluminum cover that stocks engine oil. The piston movement after the combustion is the result of combustion over that, in other words, the energy of combustion manifests itself in piston movement.

Cycles:

Any type of internal combustion engines operates following phases of operation, these are followed rigidly. All phases are called cycle, this is a group of phases that converts the combustion energy in piston movement.

There are two types of cycles that internal combustion engines operates. They are:

- Mechanical cycle;

- Thermal cycle.

The mechanical cycle is defined by the engine features and determines how air/fuel mixture and combustion gases are distributed inside the cylinder and released from it. This process follows the engine strokes.

The thermal cycle features the preparation and operation of air/fuel mixture as well as the engine operation, this cycles can be used for all types of thermal engines.

Four strokes mechanical cycle

This cycle starts when the piston are on intake top dead center (TDC), the intake and exhaust valves controls the inlet and exit of air/fuel mixture and combustion gases respectively.

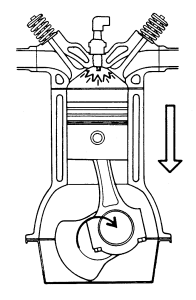

1º stroke – Intake: The piston are on intake TDC and starts to move to bottom dead center (BDC) while creates a negative pressure inside the cylinder. The intake valve opens and a determinate amount of air/fuel mixture enters. The crankshaft rotates 180º.

2º Stroke – Compression: Since in BDC, the piston moves upward to TDC compressing the air/fuel mixture. The intake valve closes and the exhaust valve remains closed. Arrived in TDC, the piston compressed the air/fuel mixture and, with engine head, formed the combustion chamber. The crankshaft rotated more 180º and completed 360º, one turn.

3º Stroke – Combustion/Expansion: At TDC of compression, the spark plug produces a spark that initiate the combustion of the hot and compressed mixture. A great amount of energy is produced by combustion, the combustion gases suffer a expansion and pulls the piston to BDC. This is the only stroke that produce energy. The crankshaft rotates more 180º, now with 540º rotated.

4º Stroke – Exhaust: After reached BDC, the piston moves back to TDC. Meanwhile the exhaust valve opens to release the combustion gases. When piston reaches TDC, the exhaust valve closes and the intake valve opens to initiate a new cycle. At the end of cycle, the crankshaft completes two turns.

Technical features of four stroke mechanical cycle

The crankshaft completes two turns for each cycle, that is 720º, and for each stroke 180º of rotation is completed by that. The piston moves to TDC in two moments, first is the compression stroke, when both valves are closed and the top of piston and the engine head forms a combustion chamber. The other moment is TDC of valves balancing or, some literatures called, the 5º stroke. Actually is short moment that intake and exhaust valves are open, and this moment is used with refference for engine point adjustment.

Two strokes mechanical cycle

This cycle began when the piston is on TDC, the crankshaft completes 360º of rotation. The inlet and exit of air/fuel mixture and combustion gases are controlled by the piston movement, when this open or close the intake and exhaust windows.

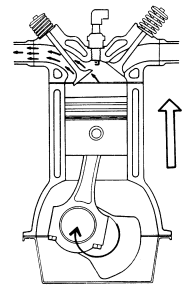

1º Stroke – Intake/Compression: After combustion, the piston start your downwards movement. During it, the piston open the escape and decanting windows, then the air/fuel/oil mixture pre-compressed on carter pass through the decanting and reach the combustion chamber. This movement of the mixture also pulls the combustion gases out off the combustion chamber. The crankshaft completed 180º of rotation.

2º Stroke – Combustion/Exhaust: The piston began your movement to TDC, meanwhile it closing the exhaust window and opening the intake window,by this the mixture air/fuel get in and mix with engine oil. The air/fuel/oil mixture in combustion chamber are compressed by the piston when it reaches TDC, the spark plug released a spark that initiate the combustion. This pulls the piston back to BDC, during this movement, the piston opens the exhaust and decanting windows. A new charge mixture entries on combustion chamber and a new cycle began. The crankshaft completed more 180º, at the end of cycle 360º of rotation was completed by the crankshaft.

Technical features of 2 stroke mechanical cycle

This cycle has two strokes, but one of these is power stroke, therefore is necessary a flywheel bolted on crankshaft. On two stroke cycles, the intake charge has to be big enough to completely expel the combustion gases from the combustion chamber. The air/fuel mixture also mix with engine lubricating oil, because in general application of this type of engine, a lubricating system does not exist. Therefore, the air/fuel/oil mixture lubricate pistons and cylinders when it reaches the combustion chamber.

The two stroke engine also have one more particularity, decanting. For this become possible, the mixture must be pre-compressed. This occurs in three different ways:

1 – Carter pre-compression: Before the mixture arrive on combustion chamber, it was on carter. The piston opens intake window during the first stroke, the mixture gets inside carter. When piston initiate your downward movement, the mixture is pre-compressed, but in some point of that pistons movement, the decanting window is open. Then, the mixture is pulled to combustion chamber. Owing this becames possible lubricate the internal parts of the engine. The most characteristic of two stroke engines are the white smoke from burned oil getting out from cars and go-karts.

2 – Special piston: A special piston, is used to intake air/fuel mixture and pump it to decanting passage in the moment of this is open. For this, a sync between the special piston and crankshaft is provided, when piston are moving to BDC and open the decanting window, the special piston pumps the mixture to combustion chamber. This solution was used in two stroke diesel engines.

3 – Compressor: In this configuration a compressor is used to pump air/fuel mixture to each decanting of the engine. Then, each cylinder are feeded with mixture on the moment of piston open the decanting window. It is not necessary more than one compressor to feed each decanting passage of each cylinder, because that feeds a chamber before each decantig. Thereby the mixture is guided for each cylinder as piston opens decanting window.

A two stroke engine is faster than a four stroke engine, some weaknesses are observed in two stroke engine, and these led it to disuse in automobiles applications, however. In two stroke engine only one stroke is productive, the crankshaft executes one turn and this means one cycle. Your engine speed and configuration contribute for a weak air intake.

In this cycle, intake and exhaust occur at a short period of time, the decanting phase and exhaust are simultaneous. This is harmful to engine when it operate at low and high revolutions, because some part of the fresh mixture goes straight from decanting to exhaust. Due to this the engine burns only a part of air/fuel mixture, reducing your energy production. Because of this, two strokes engines produce less energy than a four strokes engine. However, two strokes engines are so fast that it produces specific power around of 1,2 – 1,5 times higher than a four stroke engine with same cubic inches and speed.

Thermal cycles

Thermal cycle describes the preparion of air/fuel mixture and features the transformation of combustion energy in mechanical energy. Thermal cycles are also divided in phases, but in this case describing how air/fuel mixture is prepared, as well as pressure variation, expansion and exhaust of combustion gases.

Two thermal cycles are most used in automobiles aplications, they are:

- Beau de rochas/Otto;

- Diesel.

Beau de rochas thermal cycle

1º phase: Intake of stoichiometric air/fuel mixture;

2º phase: Compression of air/fuel mixture at controled pressure to avoid engine knock;

3º phase: Ignition of air/fuel mixture by the spark plug;

4º phase: Progressive combustion of air/fuel mixture;

5º phase: Expansion of combustion gases;

6º phase: Exhaust of combustion gases, theses gases are composed of:

Water steam;

Carbon dioxide;

Carbon monoxide;

Nitric oxide.

Diesel cycle

1º phase: Maximum air intake;

2º phase: Compression of aspirated air;

3º phase: Injection of fuel on compressed air;

4º phase: Spontaneous combustion of air/fuel mixture;

5º phase: Expansion of combustion gases;

6º phase: Exhaust of combustion gases, these are composed of:

Water vapor;

Carbon dioxide;

Soot;

Excess air.

For engines that obey the Beau de Rochas cycle (or simply Otto), the air/fuel mixture determines the power of engine, it must be on stoichiometric proportion. In other words, the enough amount of fuel need to totally burn the air admitted. The engine can not surpass the pressure limit of fuel, otherwise the engine knock will occur. The compression limit is determined by fuel octane rating. For gasoline or ethanol, different values of air/fuel ratio are used.

After combustion, the expansion of gases occur at 20 m/s and a maximum of 40 Bar, this pressure peak is not obtained with piston rigorously on TDC. For a better used of combustion power, the combustion occur when a crankshaft are slightly inclined before the point relative to piston TDC. The purpose of this is align the direction of combustion power to direction of piston (and crankshaft) movement.

The diesel cycle has some particularities in comparison with otto cycle. The amount of air, for example, is always highest as possible. The power control is determined by the amount of fuel injected in combustion chamber at end of compression stroke. The pressure on that stroke is at least 35 Bar.

The fuel injected mixes with compressed air and spontaneously burn, so diesel engines do not need spark plugs. After combustion, the gases expansion occur at a pressure range of 80 – 100 Bar.

The reason for diesel engines have more efficiency than otto engines is due to enormous amount of admitted air. Although only part of the air is used in combustion, the other part, not burned, is in contact with combustion gases, that are at high temperatures. The air no burned heats producing an additional work over the piston.

Engine components

The internal combustion engine is divided in three basis parts, they are:

- Engine head;

- Engine block;

- Engine power-train.

Engine head: It is responsible for house valves, camshafts, valve guides and valve seats, in addition forms the combustion chamber when pistons are in TDC.

Engine block: It is most important part of the engine, inside the block are cylinders, that where pistons alternatively moves connected with rods, and these connected with crankshaft. Also, the engine block provides support for crankshaft and your bearings, houses ducts of lubricating and accessories components like alternator and a/c compressor.

Engine block: It is most important part of the engine, inside the block are cylinders, that where pistons alternatively moves connected with rods, and these connected with crankshaft. Also, the engine block provides support for crankshaft and your bearings, houses ducts of lubricating and accessories components like alternator and a/c compressor.

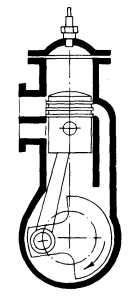

Engine powertrain: The engine powetrain are composed of the pistons, rods and crankshaft, these part produce mechanical energy and transform it in rotary movement .

Engine powertrain: The engine powetrain are composed of the pistons, rods and crankshaft, these part produce mechanical energy and transform it in rotary movement .

Engine systems

For rightly operation and high durability, the engine has vital systems, they are:

- Cooling system;

- Lubrication system;

- Fueling system;

- Electric system;

- Distribution system.