Consecutive engine combustion causes the engine to reach extreme temperatures within the combustion chamber (2000 ° C). This would lead to the complete destruction of the engine if there was no cooling system that would remove heat from the combustion chamber walls. The various engine components operate at different thermal gradients, and the cylinder walls cannot exceed the limiting temperature of the lubricating oil (150 ° C).

Directly in contact with combustion, the pistons work at a temperature of 320 ° C, the limit of their material (aluminum alloy). The combustion chamber reaches around 200 ° C, while other components also connected to combustion work at higher temperatures. Intake valves (120 ° C) in turn have the air / fuel flow that removes heat from them at the time of intake, but the exhaust valves (750 ° C) work under constant thermal stress because the gases in the combustion are removed from the combustion chamber through it, as is the spark plug (500-600 ° C) that performs combustion.

The valves can exchange heat with their seats and guides, and the plugs drain their temperature to the head, and finally the coolant exchanges heat with them. The importance of the cooling system lies in the fact that the engine’s internal temperature must be such that the oil can work with good viscosity, that the internal clearances are filled, that the flame front expansion does not reach the chamber walls and In particular, high combustion chamber temperatures should be avoided due to the detrimental effect of detonation. Thus the cooling system works to keep the engine at its ideal temperature, which is about 90-95 ° C.

The car cooling system has two variations:

- Air cooling system;

- Water cooling system.

The water cooling system has two variations:

- Thermosiphon water cooling;

- Forced water cooling.

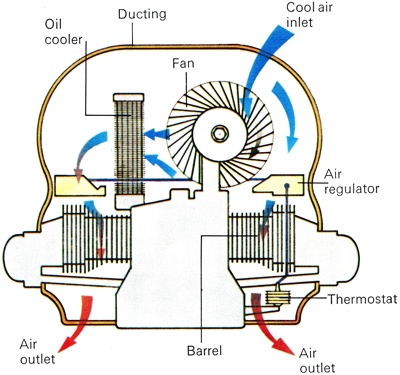

Air cooling system

In the automotive market the use of this system did not extend for long, only some brands like Porsche and Volkswagen went further in its use. This system has as its greatest feature its simplicity. There is no water circulation inside the engine, cooling is performed by the air flow through it during the vehicle travel. The operating temperature in air-cooled engines is higher than in water-cooled engines, and lubricating oil in turn plays an important role in heat exchange with internal components, which has led to the use of quality oils and radiators. oil for these engines. The oil temperature is monitored by a thermostat.

Machined fins on head ensure greater contact area with air flow and thus better cooling. Although these engines will reach their working temperature range faster, in situations of low or non-existent airflow, such as idling stops or very long climbs, cooling would be compromised. This is not due to the use of a fan, which can be mounted on the crankshaft, ensuring the necessary air flow to the engine.

However, at times when the engine had to reach or maintain working temperature, such as cold starts, high speed travel, or downhill, a shutter was often used that would stop the flow of air to the cylinder head fins. to ensure optimal operating temperature.

The limitation of this system is the fact that there is a large temperature variation during its operation, and its sensitivity to the engine’s own load variation and ambient temperature, resulting in larger design tolerances and more viscous oils. Its maintenance is linked to the belt that connects the crankshaft to the fan, and in cases of a fan directly attached to the crankshaft, there is no maintenance.

Water cooling system

The use of demineralized water mixed in the proper proportion with additive has made a major leap in the evolution of internal combustion engines. There was no longer that irregularity in the engine’s operating temperature, and the engines began to operate with increasingly narrow temperature limits. Which certainly helped increase the engine torque over the years. However, the first water cooling system to emerge was the thermosiphon, but it was still deficient at some points.

Thermosiphon water cooling system

In this system, the coolant circulates from the density difference of the fluid in the radiator and the fluid around the cylinders. The coolant contained in the radiator was less hot and denser, tending to come down. In contrast, the fluid in the engine block is hotter and less dense, so it is pushed by the fluid exiting the lower radiator duct and channeled directly into the radiator itself closing a cycle.

This ensures a good engine warm-up phase as water only circulates after the engine has reached working temperature. Nevertheless, this system requires large dimensions of the radiator and its ducts, as well as being uneven in relation to the engine, resulting in large footprint in the front, impairing aerodynamics.

The temperature difference between the engine coldest point and the hottest point can be 40 ° C, which compromises close control of the engine temperature and facilitates freezing of radiator water in cold climates. In times of poor airflow over the radiator, airflow is supplied by a fan.

Forced water cooling system

The forced cooling system has completely surpassed the old thermosiphon. Finally, it was possible to achieve tighter control over engine temperature limits, reduce radiator dimensions, reduce the temperature difference between cold and hot (<10c), and use the fluid for the vehicle’s internal heater. .

A pump driven by the engine itself pressurizes the system and ensures the circulation of coolant in the engine without having large losses in power. The pressure exerted by the pump circulates the fluid at great speed increasing the heat transfer coefficient. Fluid flow through the radiator is controlled by a thermostatic valve, which releases and ceases fluid flow to the radiator according to the fluid temperature, remaining closed when the fluid is not yet within the range of 85-90 ° C.

When the vehicle is stationary while the engine is running, airflow over the radiator is zero. To ensure this flow, an electro- fan controlled by a thermostatic switch is employed. This switch activates the electro-fan whenever the coolant temperature exceeds 95 ° C.

Circulation of coolant within the engine and radiator is made possible by the use of the thermostatic valve. This valve is directly in contact with the fluid, and when closed, the fluid flows into a channel back to the engine block. Once the opening temperature is reached, the fluid has free passage to the radiator.

Components

- Radiator Antifreeze Additive;

- Expansion reservoir;

- Radiator;

- Water pump;

- Thermostat;

- Electro fan;

- Water chamber.

Radiator Antifreeze Additive

Made from ethylene glycol, the well-known radiator additive is a fluid that must be combined with distilled water in a proportion that varies by manufacturer. The function of the additive is to raise the water pressure and boiling temperature. However, the most important functions are anti-corrosion and lubrication agents, which serve to reduce the impact of water oxidation on the engine metal and lubricate the water pump.

Expansion reservoir

Also called a water reservoir, it has no function of storing coolant, in fact these components serve to enable the coolant (combined water and additive in certain proportions) to have room to expand when it is at elevated temperatures. They are generally made of translucent plastic materials with minimum and maximum coolant volume markings. The reservoir cap has a small one-flow valve in which fluid vapors can escape from the system and not generate overpressure and allow air to enter the system.

Radiator

Wrongly called a radiator, the radiator does not use radiation to effect heat exchange between fluid and air. And yes of convection. The radiators are made up of honeycomb-shaped elements with pipes through which the cooling fluid circulates.

The first radiators had a cap called a register, which limited the system pressure during heating and water expansion. Currently there is an expansion reservoir for this, where the fluid is at a certain level, when heating the fluid level increases due expansion, also increasing the pressure.

When cold, the fluid contracts, reducing the reservoir level. The expansion reservoir cap increases system pressure by 0.3-0.5 Bar above atmospheric pressure, which raises the boiling water temperature to 110 ° C. This ensures that the coolant does not boil and boil in the most varied weather conditions the vehicle may face.

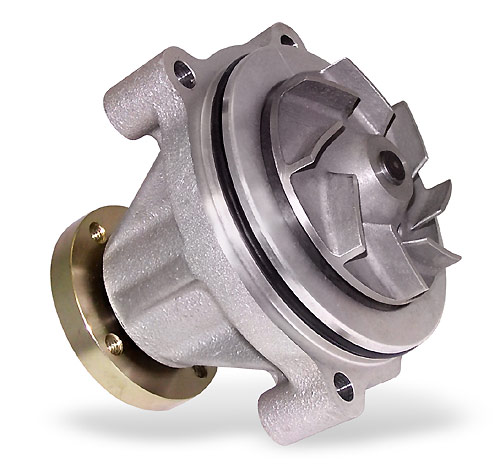

Water pump

A centrifugal pump that pressurizes and accelerates fluid circulation over the engine block. This pump is attached to the crankshaft by a V-belt made of rubber. Use of the additive contributes to pump life, the additive lubricates the moving parts of the pump and prevents oxidation.

Thermostat

This valve has the important function of controlling the engine working temperature. It consists of a cylindrical capsule in which it has a solid state wax sensitive to temperature variations. When the engine reaches a temperature above the limit temperature for the valve to remain closed, the wax warms and melts, pushing the stem and opening the coolant passageway to the radiator.

Water chamber

It is the space through which coolant circulates throughout the engine block and cylinder head. The water chamber places the coolant in contact with the cylinder walls, valve seats, and valve guides to exchange heat with these components for cooling. Its water inlet is located at the bottom of the block, which is connected to the lower radiator duct, and its water outlet is positioned at the top of the block, connected to the upper radiator duct.

Maintenance

The cooling system works by using the cooling fluid, which is the proportional mixture of water (preferably demineralized) most additive (usually 40%) for radiators. This additive contains properties that alter the boiling water temperature, prevent engine corrosion, combat limescale formation and provide some lubricating power over the engine water pump. Even with the use of the additive the system is not maintenance free, the replacement of the liquid is done at periods determined by the vehicle manufacturer.

When lack of maintenance prevails, there is a serious problem of scale limescale suspended in the coolant. This occurs when the fluid is under low temperature (about 55 ° C) and limestone forms crust throughout the system reducing the thermal conductivity of metal walls, and in extreme cases, may even clog the system ducts impairing fluid circulation.

The cleaning treatment of the system to dissolve the crust is very aggressive. It is recommended that the radiator and block be inspected for possible leaks. For the substances used often expose leaks that were previously covered by the crust.

First, the system is cleaned internally against dirt, oxidation and debris in suspension by adding a solution of water and caustic soda (2-3 kg for every 10 l of water) and running the engine at medium load for 10 minutes. The entire solution is removed from the system.

After this step, a solution of hydrochloric acid (20-40%) and water placed in the engine cooling system is used to dissolve the crust. The engine is started for about 10 minutes, then the solution is removed and the internal cleaning performed. In most cases this procedure is done more than once, it all depends on the level of system contamination.

References

- SENAI, Série Metódica Ocupacional;

- CHOLLET, H. M., Curso Prático e Profissional para Mecânicos de Automóveis: O motor e seus acessórios, Lausanne, Hemus, 1996. 402;

- BOSCH, Robert, Manual de Tecnologia Automotiva. 25.ed. Edgard Blücher LTDA, 2004. 1231p.