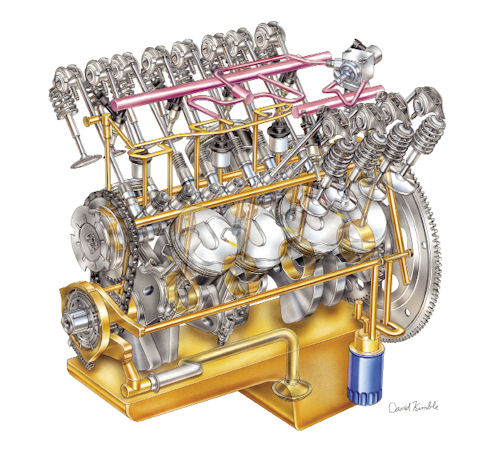

An internal combustion engine is designed to operate for hundreds and even thousands of kilometers. To make this possible the engine is provided with a lubrication system, otherwise it would not last a few minutes. This would happen due to incessant movement of parts inside the engine, and these parts are in contact with other parts of the same or similar material.

The lubrication system ensures that these parts work with an oil film between them (wet friction), which considerably reduces friction and consequently wear. In addition, the system also performs a small refrigerant auxiliary function to the cooling system, retains airborne particles that may reach the lubrication channels under intense work of the power parts, prevents oxidation of the parts and the formation of carbonization.

Friction Types

As much as it may seem, the engine parts do not have smooth and uniform surfaces, on the contrary, they are full of ridges and contact with the other parts would generate a great friction were not the action of the oil. The oil molecules form a film between the two pieces, filling the space between the ridges of the two pieces. However, the formation of this film is hampered by the pressure exerted by the parts, which wear the oil film between piston and cylinder wall, metal-to-metal contact becomes inevitable. Film formation and wear to contact between parts is characterized by three levels of friction:

Net friction

The oil film between parts remains intact preventing contact between parts during engine operation;

Wet friction

The oil film begins to wear and at some points there is contact between the piston skirt and the cylinder wall;

Dry friction

The oil film has been completely removed from the cylinder wall, leaving the engine exposed to harmful piston-cylinder contact.

Lubrication Types

The development of the internal combustion engine went through several phases and in them the engine systems were being improved. With this, some types of lubrication systems were emerging, either by development or by using the engine.

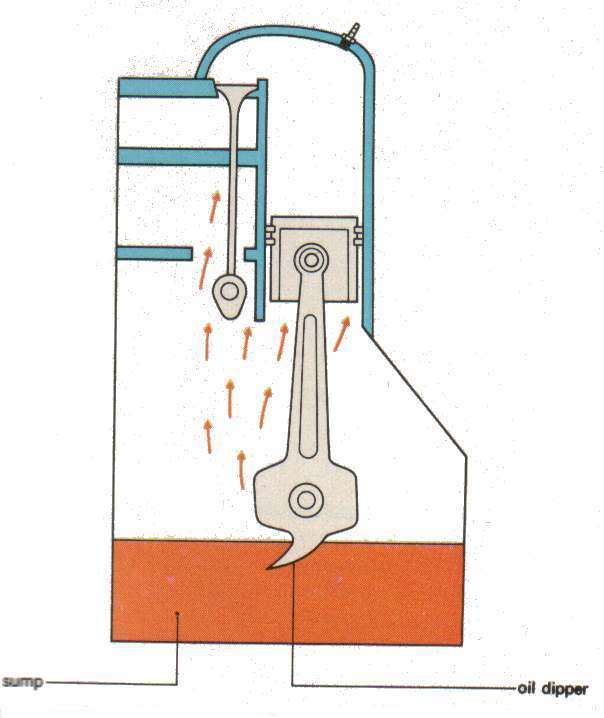

Splash Lubrication System

In this system the oil pump keeps some tanks full of oil, they are purposely positioned near the passage of each connecting rod. The connecting rods are provided with a spoon and collect some of the oil during their back and forth movement. Oil penetrating the connecting rods lubricates their connecting rod. This is a system that requires larger lubrication channels due to its low operating pressure (0.1 to 0.4bar).

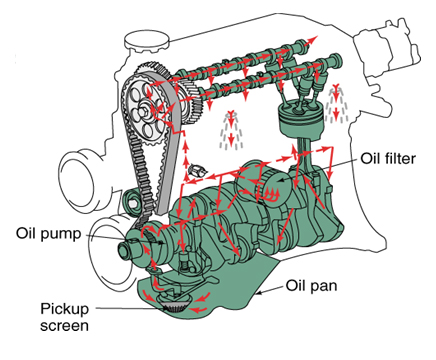

Pressure lubrication system

This successful lubrication system uses pump pressure (1 to 3 BAR) to reach the various engine oil pipelines. Crankshaft sleeves and crankshafts have lubrication holes through which pressurized oil reaches the connecting rods. Oil pipelines also direct oil to the cylinder head parts (camshaft, rocker shaft, tappets …). The connecting rods have an internal conduit that extends from the head to the connecting rod to the piston pin. To then pour oil jets that cool the piston. In this system oil blowers are also very frequent, which pour oil jets towards the pistons or cylinders.

Projection Lubrication System

This is a variation of the pressure lubrication system. In this bearing and crankshaft they are pressure lubricated, while the connecting rods are lubricated by projection of an oil jet. An oil channel under pressure pours oil jets onto the connecting rod, which with a spoon can channel these jets internally promoting lubrication of the pin-piston assembly as well as much of this oil reaches the connecting rod head, promoting cooling. The working pressure in this system ranges from 1 to 3 BAR.

Mixture lubrication system

Inefficient and obsolete. This lubrication system uses lubricating oil proportionally mixed with fuel, and has been widely used in two stroke engines. The oil ratio could not be overstated, which impaired combustion performance (hence power) as well as contaminating combustion chamber and exhaust window. Currently this system features in small two-stroke kart engines and small radio-controlled cars.

Dry oil pan lubrication system

This is the most successful and efficient lubrication system. It has two working oil pumps, one removing oil from the crankcase and sending it to an external reservoir, and another bypassing the oil from that reservoir to the engine. Aimed at high performance and competition cars, its biggest advantage is that it can work with the oil at a lower temperature, as well as making it possible to mount a smaller crankcase, thus allowing the engine to be placed lower on the body.

Operation

When the vehicle is started, engine power also rotates the oil pump, which is coupled to the crankshaft pulley by a belt. The pump supplies pressurized oil through all lubrication pipelines in the engine. Although this ensures lubrication of moving parts, the cylinder walls have lubrication guaranteed by splashing or spraying oil onto them whatever the type of lubrication system. This is due to lack of lubrication in the first few minutes of engine operation, which is almost nonexistent. In all this work, the oil provides the lubrication and cooling capacity of the engine internal parts, and can reach up to 120 ° C when exiting the connecting rods. In the cylinder walls the oil can reach its limit temperature of 150 ° C. When it returns to the crankcase, it is cooled by the external air stream, where it lowers its temperature to about 80 ° C. Depending on the engine design, an oil cooler may be required for better lubricant cooling.

Components

The lubrication system consists of the following components:

- Lubricant;

- Bomb;

- Oil filter;

- Oil fisherman;

- Crankcase;

- Oil cooler.

Lubricating oil for internal combustion engines

Basically, lubricating oils are fluids that serve as the interface between two relatively moving surfaces. This is their main function, but in addition to this there are also important friction reducing agents, cooling aids and corrosion reducers.

In the case of automotive internal combustion engines, this function does not change, but there are differences in the additives of these oils and in the viscosity indexes. This is due to the medium in which the oil is inserted, in which there is contact with combustion residues, the fuel itself, as well as the conditions of temperature and internal pressure of the engine and temperature of the medium in which the car will be used.

Briefly, for the above reasons, automotive lubricating oils are of the mineral or synthetic type and multigrade, with constant updating of their formulation and additives.

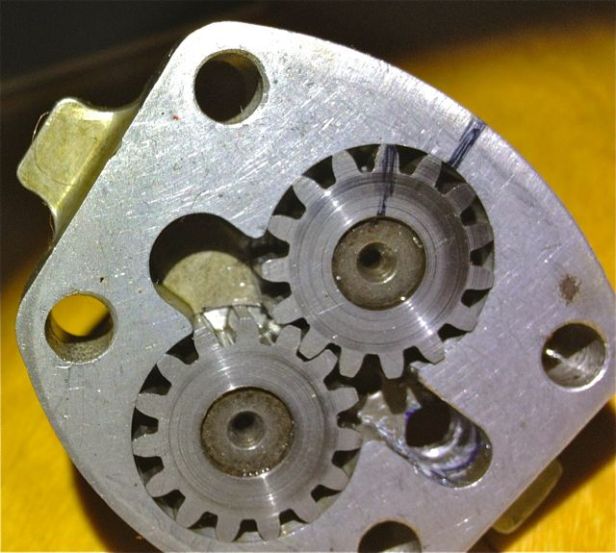

Oil pump

Powered by crankshaft. Oil is sucked from the crankcase by the pump through the oil angler, then sent to the engine lubrication channels, and returned to the crankcase by gravity. There are several types of oil pumps, the most common being gear and rotor pumps.

Oil Pump – Gears

This type of pump consists of two gears contained in a minimal clearance housing. Driven by crankshaft or camshaft, the gears when turning fill their oil gap, which after the teeth are engaged with pressure (usually 3 BAR) for all engine lubrication channels.

Oil Pump – Rotor

This pump consists of two concentric rotors, one external and one internal. The rotors are contained within a cylinder, rotate and the space between them is filled with oil. The outer rotor has one more shoulder than the inner rotor, which when rotating on one side sucks the oil and on the other impels the oil under pressure to the lubrication channels.

Oil filter

After miles of operation, it is normal for the oil to retain a certain amount of impurities, to prevent these impurities from clogging or causing premature wear on components where the oil works under pressure, the oil filter is used. This component is usually positioned just before the oil reaches the oil pump. It is composed of a metal casing containing a resin impregnated paper. The oil is directed to the oil filter by tapping, or full filtration. In the first case, only part of the oil goes to the oil filter (10%), while the other part goes to the crankcase. The second case, all the oil goes through the oil filter. Upon entering the oil filter, the oil follows a high speed circular path inside the filter, the resin impregnated paper retains the oil impurities. If the amount of impurities is excessive to the point of clogging the filter, it has a valve that diverts the filter oil when the internal pressure reaches a certain value, preventing the system clogging. This valve is known as a bypass valve, and also acts during cold start due to the thicker oil.

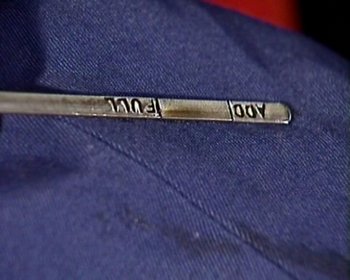

Oil duct

This component consists of a tube of metal or plastic material, with one end bolted to the engine block and the other end dipped in oil in the crankcase. This end has a small metal mesh that acts as a filter, preventing macroscopic impurities from reaching important lubrication channels, causing wear or clogging.

Oil pan

Usually made of aluminum alloy, the crankcase is basically the engine oil reservoir. All engine oil is trapped in the crankcase. In addition, the crankcase also aids in oil cooling when receiving contact with outside air during engine movement. The crankcase is fixed with screws that have the specified torque and tightening sequence.

Oil cooler

Positioned close to the engine radiator, the function of the oil cooler is to promote rapid heating of cold running oil and to prevent it from reaching temperatures exceeding its working limit (150 ° C). Since the oil has an ideal working temperature, the oil cooler aims to normalize that temperature. It can be mounted in series or bypass, in the latter the system has a second pump that impels the oil to the radiator. Although it is used according to the engine needs, the oil cooler has been widely used in air-cooled engines, because in these the oil cooling action is fundamental.

Water and oil heat exchanger

An efficient solution to keep the oil at its ideal temperature is called oil-water heat exchanger. Similar to the oil-to-air oil cooler, the heat exchanger has contacting coolant and oil circulation channels. This facilitates the oil to reach the ideal operating temperature, as when the fluid warms up, heat exchange with the oil. And when its temperature rises in excess, it is cooled by the coolant keeping at the ideal working temperature.

Maintenance

The main maintenance of the lubrication system is the oil change. It is a preventive maintenance, which when neglected ends up impairing the life of the engine. In detail a waste oil has a high level of impurities and instability of its additives, these impurities are carbon, fuel, bituminous materials, metallic particles and acidity. The carbon comes from burning the oil itself, contaminating the entire combustion chamber and can reach the oil itself.

The presence of fuel in the oil is due to the rich mixture used at cold start and during the engine warm-up phase as fuel particles can condense and reach the lubricant. Bituminous matter arises from oil contact with the engine’s internal air, which generates oil oxidation.

Worn motors can release metal particles that are carried by the oil, which is very harmful to the engine if it reaches a point where the oil line is exposed to too much pressure. The longer the oil change is delayed, the more acidic it becomes, the quality of the oil also influences this acidity level.

Due to the above facts, it is recommended that the engine oil change strictly follow the manufacturer’s instructions.

References

- SENAI, Série Metódica Ocupacional;

- BOSCH, Robert, Manual de Tecnologia Automotiva. 25.ed. Edgard Blücher LTDA, 2004. 1231p;

- CHOLLET, H. M., Curso Prático e Profissional para Mecânicos de Automóveis: O motor e seus acessórios, Lausanne, Hemus, 1996. 402.