One of the most traditional and efficient techniques to produce metal parts for automotive and general industry is casting. It can be manual, automated, modern or rusting, casting always delivers parts with high quality and with a complex shapes that few process could obtain. This article will review the main techniques and their common issues.

Types

- Sand casting;

- Die casting;

- Evaporative pattern casting.

Casting issues

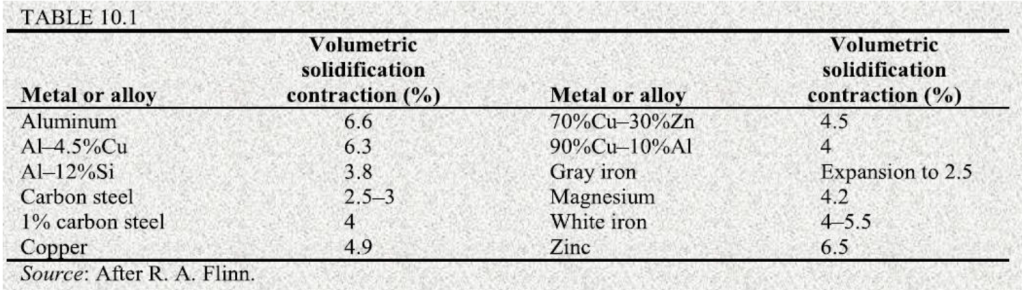

Although very versitile, casting parts exhibit traditional issues that must be managed by desing engineer or department. The main issue is the shrinkage, as can be seen on the Table, each material exhibit a degree of distortion due to the process. In general, a contraction produces dimensional incosistencies in the parts produced by casting. The shrinkage usually occur during material cooling, mainly in the cooling until room temperature. Kalpakjian and Schmid (2009) describe three stages of the shrinkage process:

- Contraction of the molten metal as it cools prior to its solidification;

- Contraction of the metal during phase change from liquid to solid (latent heat of fusion);

- Contraction of the solidified metal (the casting) as its temperature drops to ambient temperature.

As can be seen on Table above, the gray cast iron is the only that exhibits a expansion instead of contraction. This occurs, because graphite has a relatively high specific volume. When they precipitate graphite flakes during the solidification they result in the net expansion of the metal.

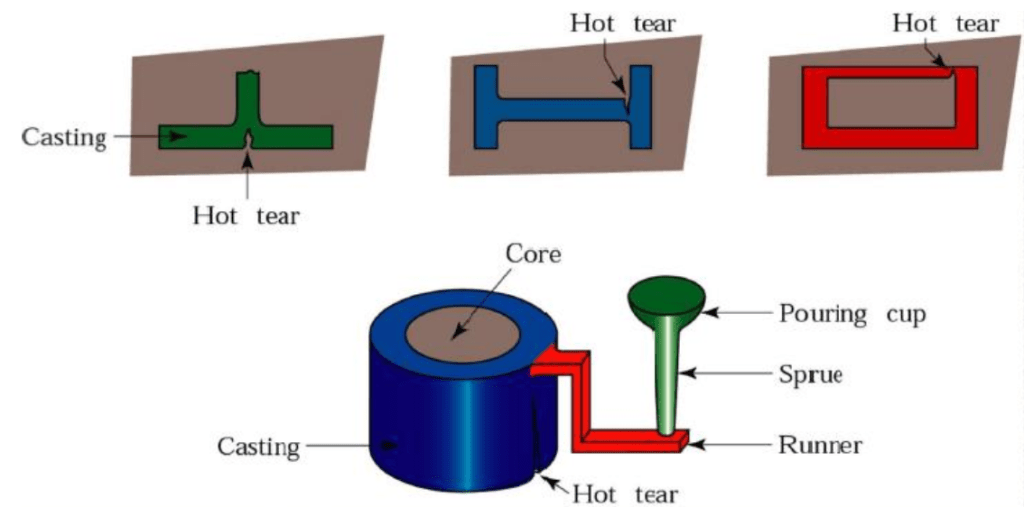

Another common casting issue is the hot tears. The casting cannot shrink freely owing to constraints in various portions of the molds and cores. This problem can also occuring the proper casting not only in casting made parts.

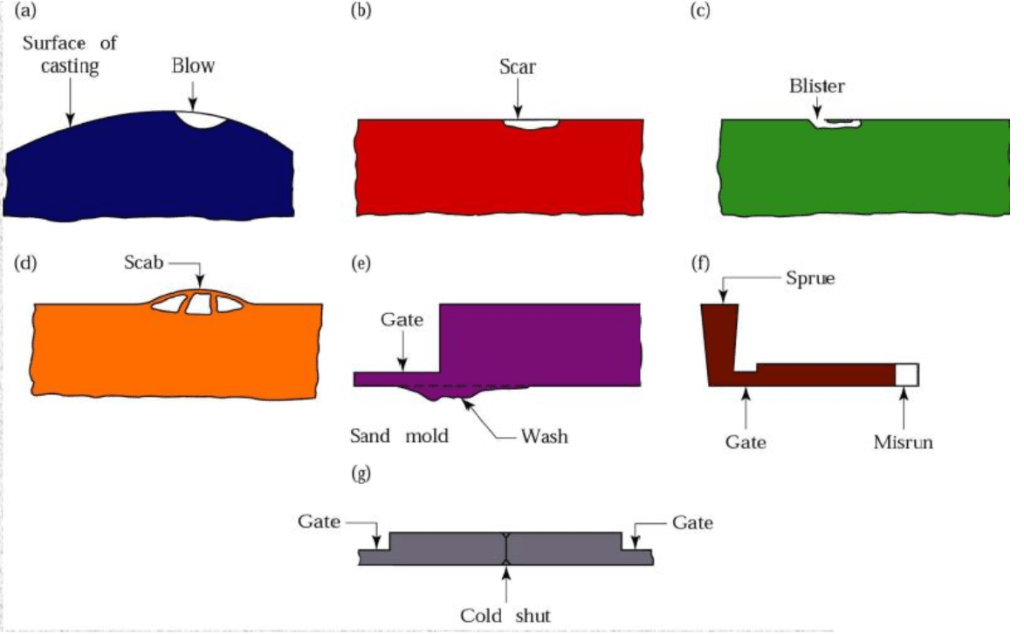

Beyond shrinkage and hot tears there are another defects in minor degree. These deliver some problems in the casting as the solidification of the moltem metal before to reach the core and and mold or insufficient amount of molten metal poured. In addition some debris in the casting can result in scar, wash, blister, scab and blow.

Porosities

In casting a thinner section will solidify faster than a thicker one. As a result the metal flows into thicker regions that are not solidified. Hence this develops a porositie in their central region as can be seen in the Figures bellow. Porosities are caused by shrinkage, entrained and dissolved gas or both ocurring during casting. Although is a simple issue there are several ways to avoid. For instance:

- Adequate volume of molten metal;

- Use of chills;

- Subject casting to a hot isostatic pressing;

- Making the temperature gradient steep.

Chills are used to increase the rate of solidification in regions that has thinner and thicker sections that generates the porosity. They can be internal or external and made by the same material of the casting.

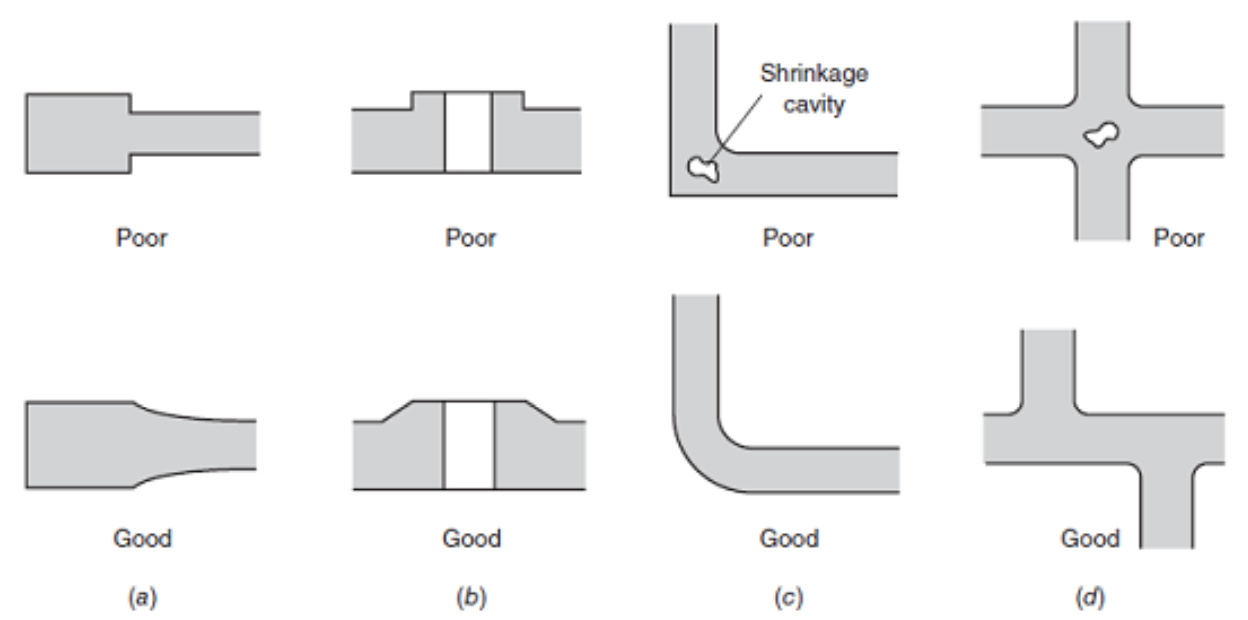

Design for casting

Understanding that casting process has several problems and some of them are cause by part inadequate shapes. It is a good practice to avoid edges as can be seen on the Figure above and use fillets and chanfers.

Another good practice is to avoid irregular surfaces. These can result in a complicated core shapes that difficult the molten metal adherence.

References

- Serope Kalpakjian, Steven Schmid – Manufacturing, Engineering and Technology-pearson (2009);