The automotive passive safety is the hability of the car to protect the driver and the passengers during an accident that could not be avoided. To success in this the automobile has several of targets to reach:

- Avoid fatal injuries of the driver and the passengers;

- Avoid fuel lekage;

- Avoid electroshock risk (Electriv and hybrid vehicles);

- Ensure the emergence egress of the all occupants;

- Minimize non-fatal injuries.

In the middle 1960 some automotive manufacturers literally driven their cars agains a wall, with the driver jumping from it in the last moment, to evalluate the safety degree of the vehicles. Nowadays many procedures, tests and evaluations preceds the most expensive and important test, the crash test. This is a physical test on real vehicles and using instrumented dummies that follows rigid standards.

Europe Union (EU) homologation

There are several crash test in EU homologation. These can be conducted in the entire vehicle, the car interior or just the seat belt. They can be static or dynamic. In addition there crash tests to evaluate pedestrian impact and injuries. Hence they can be summarized as:

Car crash tests:

- ECE 94: front crash test;

- ECE 95: side crash test;

- ECE 34: rear crash test.

Component crash tests:

- ECE 14: seat belt ancorage;

- ECE 21: interior energy dissipation;

- ECE 127: pedestrian impact.

ECE 94 – frontal crash test

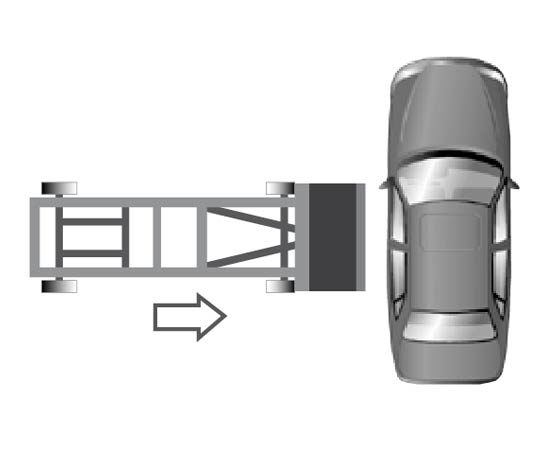

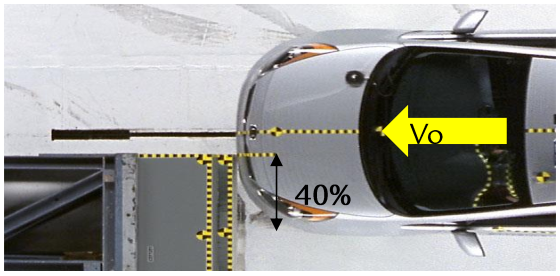

The traditional frontal crash test is performed by a real car, that can be a prototype or pre-series model, connected to a rail that tows the car reaching 56 km/h toward a fixed deformable barrier. The test is conducted using a dummie that represent a 50% percentile of the population and a barrier with an offset in the frontal area of 40%.

ECE 95 – side crash test

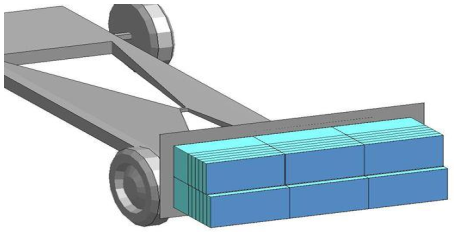

This is a static crash test. A real model is placed in the path of a trolley. This is launched toward the side of the car at 50 km/h. The trolley front has deformable barrier similar one used in the frontal crash test, but called mobile deformable barrier (MDB). Its mass is 950 kg and the MDB can also have 40% surface offset. As in frontal test, the objective is to evaluate the deformation of the vehicle body and how much it invades the body interior. In addition the dummie is equiped with sensors and accelerometers.

ECE 34 – rear crash test

Another static test, but this do not need dummies. The rear crash test evaluate the degree of deformation of the car rear. This is a deformable zone made by special steel alloys and/or aluminum with the objective to absorb the energy impact. The vehicle is held standstill while a trolley is launched at 38 km/h toward the vehicle tail.

Dummies for crash test

The main dummies used in EU crash test are the 50 percentile male, for front impact tests and also called hybrid III and the Eurosid 2, for side impact crash test. They reproduce the biomechanical parameters for a front impact as head, neck, torax and legs. In addition they also do the same for a pedestrian, which is knee shear, knee angle and tibia shear are most important points.

The Hybrid III dummie has 78 kg and 13 sensors spread through the body. 3 axial accelerometer in the head, 3 axial accelerometers and potenciometers in the thorax, 6 axial load cells in the neck, 2 load cell in the femurs and 2 loads in the tibias. The eurosid has 72 kg and 8 sensors, 1 potenciometer mounted on upper, midle and lower rib, 1 abdomen load cell, 1 pelvis load cell and 3 axial accelerometer on the head.

Restrain system design

The restrain system comprises all the components that avoid the driver displacement from the seat during a crash event. Therefore these are seat belts, seat, airbag, steering wheel and column mechanism. Their development obey the same stages as other car components as:

- Target definition;

- Target deployment;

- Conceptual validation;

- Design validation;

- Process validation;

- Homologation test session.

The target definition are based in the homologation standards, the rating required to obtain the highest level of safety, the safety margin that the component can obtain to guarantee the occupants safety and good practices of engineering. The next stage is the target deployment that gave engineering metrics to what was defined in the target definition. For instance, performance of the restraining system and the chassis. The concept validation is the phase that the first pre-designed interiors are build, even simplified. In general they are used to evaluate if the package concept of the car interior is capable to deliver, at least, the safety margin. Hence there are prototype crash tests and finite element method (FEM) analysis of the interior CAD models. In the design validation the same tests before mentioned are conducted. However the numerical evaluation has improved models of the interior and the sled test, a simplified crash test that uses a sled instead of a trolley, is conducted. In addition, a prototype vehicle is also evaluated in a frontal crash test, which means that the design is an advanced stage. The process validation is where more sled test with a simplified interior is conducted to validate all the process of the crash test for the final homologation test session. This is the test that will homologate the new vehicle towards the standards and regulation. This uses a full pre series model.

Pedestrian impact development process

As can be observed there two main impacts when a pedestrian is hitted by a car, it begins on the legs and then on the head. The first are hitted by the bumper and the second hits against the hood. This also affects the car design of the exterior panels, chassis and parts located less the 150 mm from the outer skin, as engine had, manifold and anti roll bars.

Test procedure

In general the pedestrian tests are made with a representative body of head and legs. An adult test head has 4.5 kg and is hitted in slope of 65 degree while a child test head has 3.5kg and 50 degree of incidence angle. The vehicle usually is driven at 35 km/h for these two tests. In addition the area in the hood are also determined. From a the line between the hood and the bumper or headlight, a child head will hit the hood between 1000 and 1700 mm long, as an adult test head will hit between, 1700 and 2100 mm long. The leg body test has 13.4 kg and is hitted by the vehicle bumper at 40 km/h. The injuries are measured with load cells and accelerometers that must not exhibit impacts higher than 170 g. Cuts can not be bigger than 6 mm and leg bending must lower than 19 degrees.

Before to proceed to real crash tests, FEM simulation are used as predictive tool. This helps to overview the status of the project due to the large amount of information feed after several simulation runs. In addition it possible to preview the deformation in the bodies and car structure and identify if they are inside of the criteiria of approval. Hence these reduce number of prototypes built and improve the identification of problems.

The FEM model used for a pedestrian evaluation is different of the one used in front crash test, for example. Usually it has more than small elements. Understanding that some parts inside the hood must no be more than 100 mm lenght of the hood inside surface, the FEM model include the engine, connections, all components in the vicinity as complete hood, fenders, aesthetic cover and air inlets. This increase the criticity of the simulation, because each component must have the material law (Hooke’s law, for instance), properties and element types accounted. More complexity, more time to develop. Although a great concern with these parameters, some details as laboratory or enviromental temperature are neglected.

The output

After all numerical calculations, the results are tension and deformation states of the car structure, the energy description that provides the simulation reliability and dynamics. The contact force helps to understand the flow of force in each surface, for instace, head or legs and hood or bumper. The displacement of the structure indicates if there are intrusions in the contact area.

Detail about pedestrian simulations

- In majority of the tests there are an overestimation of the results, in general around 10% for more or less;

- The consistency of CAD and the FEM determinate the deviations in the test results;

- The materials characteristics must be carrefully added, as precise as possible;

- The simulation boundary conditions may provide a wrong result.

However, if the CAD and the FEM are developed properly, pedestrian simulation can provide more information than real tests, previously recognize critical issues, run many simulations and consequently generates a large amount of data and then reduce costs, that is usually translated to less prototypes and real tests.

References

- https://www.interregs.com/catalogue/details/ece-95_03/regulation-no-95-03/occupant-protection-in-lateral-side-collision/

- https://unece.org/fileadmin/DAM/trans/main/wp29/wp29regs/r095r1e.pdf

Cover image

- afl-crashtestbarriers.com/crash-test-side-impact-barriers-ece-r95/?lang=en