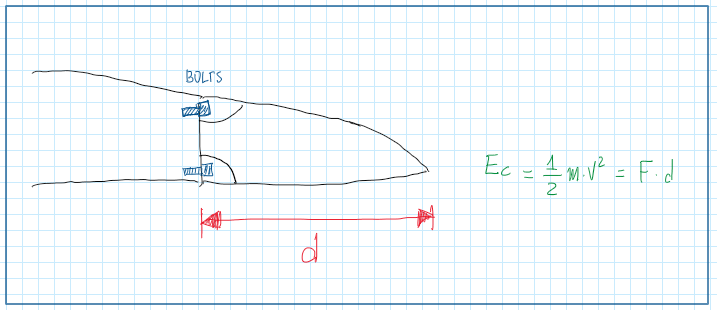

The open wheel car nose box has two functions, absorb energy and carry loads. In general this part is designed in order to be easy removable and develops a controled failure during crashing. For this reason the open wheel car (owc) nose box must have some length. Considereing the kinect energy is described by the following formulae:

Ec = 1/2*m*v^2 = F*d

It is possible to visualize that the parameter d has an important whole on the energy absorption. Considering the FIA test of nose box, this must perform a controled failure under loads about 4.000 to 5,000 kg. For this reason, the nose of owc is usually long, becase it is this distance d that is important in case of a colision. For this reason it is also important to understand the kind of loads that a owc nose box are exposed.

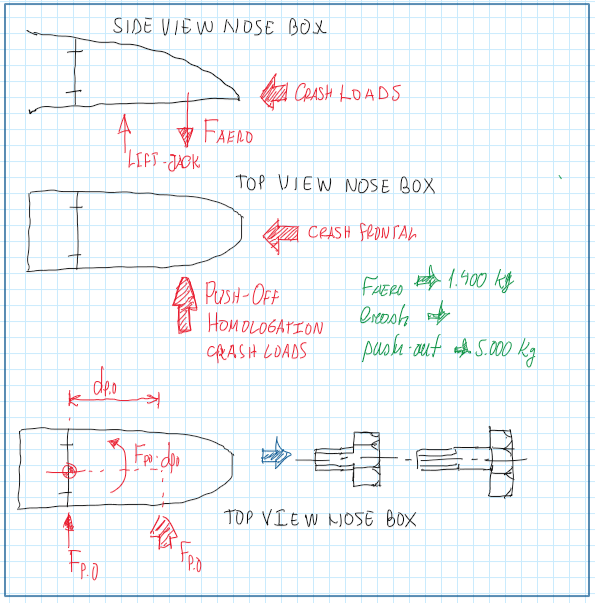

Loading

A nose box operates under the following loads, the aero force, the frontal crash forces, the jack force made during a pit-stop (formula one cars) and the push-off loads for homologation. In general, an owc with a very high aerodynamics are exposed to aeroforces about 1,400 – 1,500 kg. In addition, the push-off force in homologation by FIA is about 4,000 – 5,000 kg.

Nose box connecting

Understanding the forces which the nose box are exposed, it is possible which design the connections of the component according to the internal loads generated. For a frontal crash a compressive force will colapse the nose box which designed to progressively fails during crash. The aero force exerts a bending on the fixations, but it is the crash-off test that exposes the part to the highest stress, shear stress on the fixing points.

Fixing points

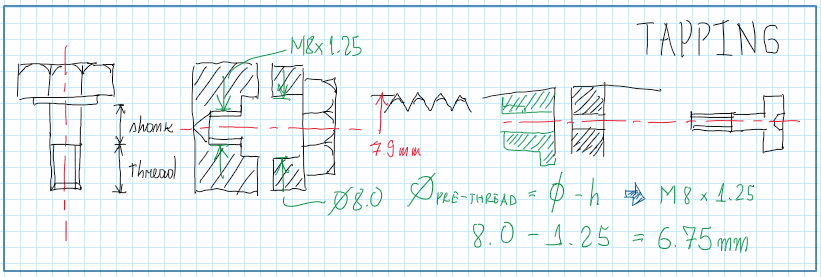

In general the nose box is fixed by bolts or studs, the choice of these components depends of the regulations. The main concern in the use of bolts is the easiness of assemble and disassemble of the component. Bolts require a proper housing and understanding that owc design have a great concern on the aerodynamics, the bolt housing is must be carefully designed. A conventional idea to use a bolt and nut can exhibit some problems.

Bolts

One of them is that both parts, the monocoque and the nose box should have treads, consenquently inserts for these. This represents more weight and, more critically, considering that race car are stiff, during races this chassis vibrates. Bolts are well known components which became loose during vibrations. Therefore another solution must be developed.

Considering the bolt of the picture bellow, it can be seen that this kind of bolt presens a section without and one with tread. The section without tread is called shank. Basically, when the bolt is fastened, the interface between the two parts will be in contact with the smooth session of the bolt while the treaded one is totally inside the monocoque, in the proper insert. The main objective of the application of this kind of bolt is to avoid that the shear stress acts directly on the treaded part. If a full thread bolt is appliead, besides the shear stress, the bolt can suffer from stress concentration.

For this, usually the pre-tread is calculated, which the tread diameter subtracted by the pitch size of the bolt. In the example on the picture above, it is possible to visualize that the pre-tread diamater is 6.75 mm, for a M8x1.25 bolt. However, it is more safe and convenient to verify the catalogs. From 6.75 mm it is possible to perform the tapping of the hole to match the bolt thread. The tapping is usually performed in small holes and these are the ones used in monocoques. In fact, most of the these have their holes threaded by taps. After tapping a common approach is the counter boring of the type spotface, which is the machining of the washer housing. The objective is to provide a place for the washer without a bolt protuberance from the monocoque surface. In addition the washer provides a better contact distribution for the bolt.

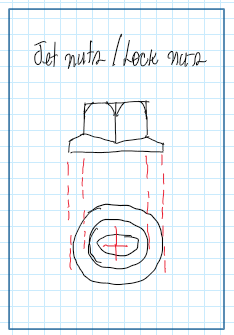

Thr main problem with bolt-nut assembling is its resistance against vibration. Race cars usually vibrates a lot due to the great load transfers and when passing over the kerbs. A common bolt-nut assembling easely became loose. In industrial field there are self-lock nuts that exhibit a very good fixing torque maintainance during use. However, they are heavy for racing field. Owing this the jet-nuts or k-nuts are often applied. These were developed for military and aerospatial applications. They exhibits elliptical hole which after well fixed, they hold the torque for wide range of vibrational conditions. In addition, jet-nuts are light and do not require a washer, but they can only be used once, because the deflection of the hole during torque application.

Studs

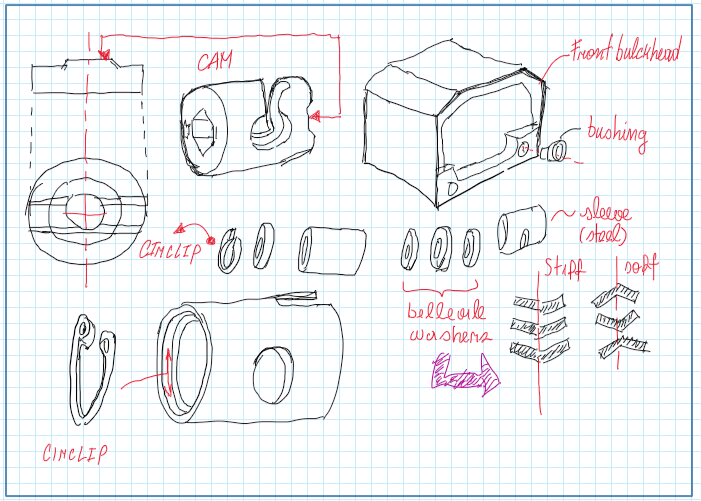

The main solution applied in the racing field for the fixing of nose boxes and the front cover of some racer cars is the stud. The advantagens of this device is its capability to hold the fixing force uniform during the use and its lightness. Considering that a proper race car is made by composite materials, the studs used in racing field are, in some degree, different than usual ones. The main arrange of racing stud is composed by the following parts:

- Cam;

- Allen key broaching;

- Counternut;

- Insert;

- Pin;

- Steel buching;

- Bellevile washers;

- Steel sleeve;

- Circlip

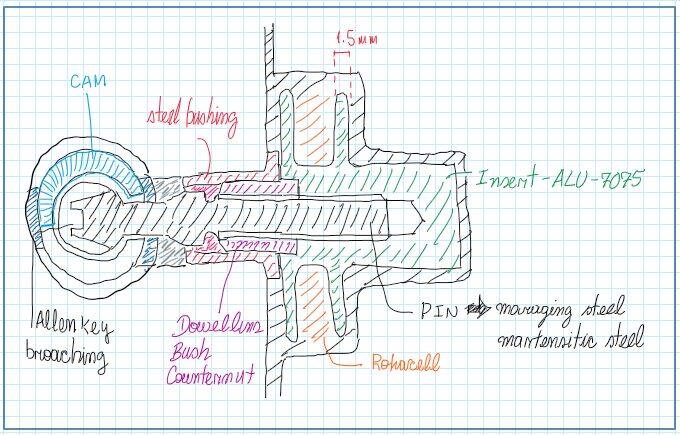

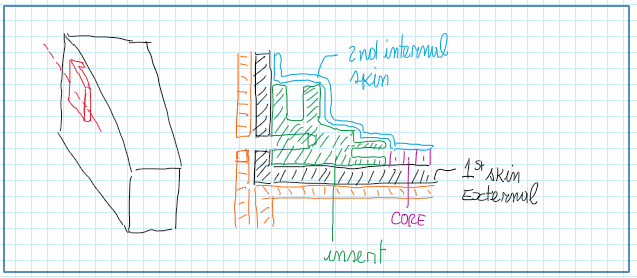

The stud is usually assembled in half parts, one in the monocoque and the other in the nosebox. This configuration is the favourite due to the precision of the machining required for hole of the stud. The machining is a less critical at the monocoque. Hence the pin is usually mounted at the nose box. In fact, the pin is the easiest part to break, thus it is better to be assembled on the nose box. In addition this also helps the mechanics, during a pit-stop, rapidly mount the nose box. The region where the stud is mounted in the nose box is the front bulkhead. A kind of aluminum insert which the holes are machined.

A bush or counter-nut is assembled in the hole and previous the pin, the steel bushing is also mounted. Inside the monocoque there is the housing for the cam which is also a housing for the bellevile washers, a steel sleeve and a circlip. The function of the cam is to lock the pin inside of it. For this a slot is provided in the sides of the cam which permits its rotation. As it is rotated the pin is hold tight by the stretching of its neck through cam. However, in this kind of fixing there is no limit to rotate the cam. Hence a mechanic solution is provided, by the use of washers, to make known at which point of the cam rotation range the mechanic is. The bellevile washers are a kind of conical springs which push-out the cap of the cam. When the force of the washer is overcomed, it makes a characteristic noise, “clack” which indicates the level of the fixing. The cam’s cap also lock on it due to the female-male connection.

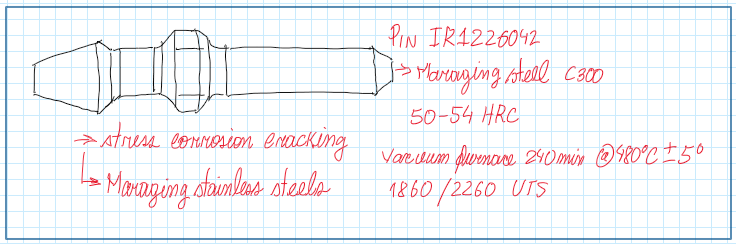

The pin is usually fixed on the insert through the counter-nut. It is made by the strong Maraging steel C300 with hardness about 50-54 HRC. The process of this part usually is a vaccum furnace of 240 minutes at 480 C to provide a pin with an ultimate tensile strength about of 1860-2260. The only concern about this part is its weakness, the stress corrosion cracking. A peculiar type of corrosion which occurs when there is an aggressive environment and very high stresses.

The insert is made by 7075 aluminum, also known by Ergal. The dimensions and the shape of the insert usually is defined with focus on the contact area increasing, because it is inserted in the carbon fiber during the autoclave cure process.

Conclusion

This is the common details about how the nose box of the open wheel race cars is made. A front bulkhead made from carbon fiber with Ergal inserts. These supports the stud structure that provide the proper fixing points for the nose box. The stud must deal with the aero forces exerted in the nose box. In addition must allow a fast assembling and disassembling of the nose box. The bolt-nut fixing type is sometimes applied at lower level racing championships due to cost and regulations which usually do not preview pit-stops.

References

- Chassis Design lecture attended in Dallara Academy.