The tire design is like a cake. Putting everything together and with the proper cook timing (curing) a tire with defined characteristics is made. In fact, tires have three main parts, the thread, the sidewall and the inner liner. Each of them is made by a different type of rubber. In addition there are different kinds of materials, as fillers, enhancers, accelerators and protectives. This article proposes an overview about the tire structure and their components.

Rubber

Tires are black, but this does not means that they are all made by the same components. There are different rubbers and compounds in the tire material composition. However, rubber is the main one. Its provenience is the latex, or the natural rubber. The latex is a mixture of polymers, the most abundant is the iso-prene, thus it is poly-isoprene polymer. However the tire rubber is not the natural one, actually this is not adivisable to be used in tires due to its low hysteresis and great promptness to oxidation. Therefore different chains of polymers are required for the tire rubber, which is the synthetic one. This have a very good hysteresis, fatigue, wear resistance and impermeability. Curiously these are characteristics that are required in different parts of the tire as the thread, sidewalls and inner liner. The main synthetic rubbers are the nitrile, styrene and poly-butadiene and they are given by the following acronyms NBR, SBR and BR, respectively.

Friction coefficient of the rubber

These kinds of sythetic rubbers also have different friction coefficients. Actually, μ is a property of the contact, thus this depends from a lot parameters relative to the tire contact with the surface. However, analyzing these components separately it is important to understand the characteristic of each one and their effect in the general friction coefficient. Between NR, SBR and BR there are no significative difference in the maximum μ obtained. However, as the sliding speed increases, the natural rubber rapidly loses its friction coefficient. NBR an SBR exhibit a wide range of constant μ while BR has a narrow range which it reaches the peak, but briefly loses this value. The tire composition is way to balance the characteristics of these rubbers in the tire thread, which defines how is the car behavior.

Rubber rebound test

The rebound test is done by an arrange which a hammer hits a rubber specimen and the height which it reaches due to the impact rebound is measured. From this it is possible to define the shore hardness of the rubber. This is intrinsically related to the strength of the rubber. In fact, strong rubbers are able to provide tire with low capability to develop lateral accelerations (high lateral g). In other words, a lower rebound of the hammer means a rubber with high hysteresis and grip. However this also results in a dilemma. A higher grip is obtained at a cost of strength, because a high hardness rubber can no provide the hysteresis required for a good grip. The tread resistance to wear is improved, although. In the racing field, tires are highly hysteretic, because grip mandatory. On the other hand, they last rapidly. As soon as tires are made by many compounds, they are also compromise between the demands made by the costumers. For instance, tires for trucks are highly strong, because the must have a low rolling resistance and high durability of the thread. In addition, they must support very high loads. However all of these characteristics came at cost of grip. In road cars, tires are softer than truck ones, they usually wear faster than truck tires and also support less loads. On the other hand, car tires have higher grip. For racing, tires are very soft in the tread, but with strong side walls and have higher wear rate than the previous examples.

Viscosity

As can be seen, the tire compound can define its hardness and strength, which are very important since these also must support hits and impacts, besides the wheel loads which are intrinsic. However one of the main parameters which also is determinant for tire operation is viscosity. As hardness, it also depends of the choice of polymers as NR, NBR, SBR and BR, but also from the vulcanization process and the reinforcing agents. The viscosity is property sensitive to speed, is a dynamic one. The deformation of a component generate breaks of atomic chains of its material. If this force is applied in a very low rate, this can be considered a static load, the deformation of the material is its plasticity if it does not return to its original shape. The energy used to deform the component is converted in heat due to the break of the atomic chains and is exchange with the environment. This is called quasi-static load. The main points in this situation is the heat and the rate, if the first is generated is because there is a significative rate of deformation, which is speed and thus viscosity. Hence each material has some amount of viscosity, damping. Rubbers are materials charcaterized as visco-elastics, because they do not behave like a elastic material. Actually, rubbers act as a spring and damper together. Viscosity are related to speed, more precisely, the relative speed between the surfaces in contact, or sliding speed. In contacts with low sliding speed, the rubber behaves like a spring, which in case of tires, it is a series o two springs due to the influence of the thread and sidewall rubbers. At certain point, the speed increases in way that the effect of the viscous damper dominates the movement. Hence the rubber changes its behavior to a viscous-elastic one. If the sliding speed is continously increasing, at certain point the viscous-elastic behavior collapses and the tire behaves as rigid connection between surface and suspensions. The grip drastically decreases. Another important concept about viscou-elastic systems is how they behave relative to stress-strain. Usually rubber exhibits a time delay between the moment which the stress occurs and the strain one. This means that tires have a brief, significative, lag after an input by the driver.

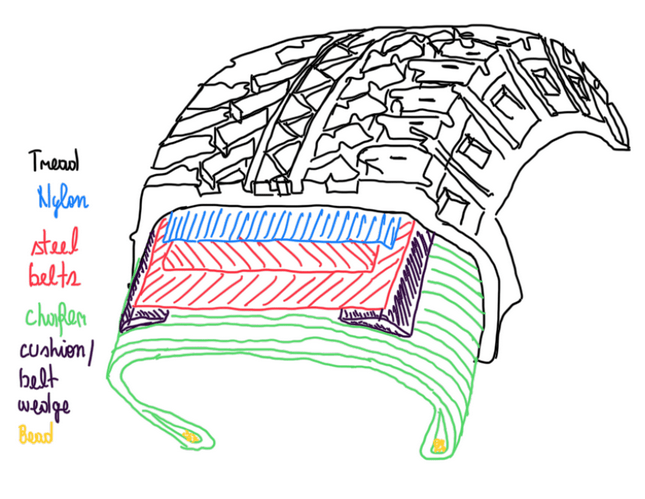

Carcass – steel wires

The tire carcass has several parts (Figure 1) made from different materials, not only rubber. Although the tread is highly important due to the grip generation, it request some support to reduced its deformation during operation. The main component in charge of this function are the steel belts. Their function is to keep the tread surface as it should be. In addition it is also good for the improvement of the torsional stiffness of the tread. The steel belts are based in steel wires that in their composition there are Mn, Si, Ph, S, Cu, Cr, Ni and Zn. The cooper (Cu) became added to work as chemical adherent for the metal chords of the carcass, because rubber does not adhere spontaneously on the steel wires. In terms of composites, the rubber would be the resin and wires would be the fibbers. Along the years new kinds of wires were

developed, for instance, Rayon, Nylon, Kevlar and Polyester. Each of them is was developed by a different tire or chemical company. The Rayon was developed by Yokohama, is derived from woods and appeared at during world war, about 1945. Nylon and Kevlar appeared in 1950 and 1970, respectively, and are used in the main ply. They are lighter than steel wires. The Kevlar is the most used in the F1 and competition tires. It was developed by Dupont. In the late 1970s, Goodyear developed the polyester, another alternative to reduce tire weight. It is usually used in the sidewalls of road and farming vehicles.

Figure 2 illustrates a graph with some alternatives to steel wires. The main point is the Young’s modulus and the tensile strength of these materials. In fact, Kevlar is the one which provides the best, or the ideal, combination. This justify its application on Formula One, because its costs are still high for production vehicles. For this application polyester and steel are more advisable.

Inner liner

The inner liner or just liner (Figure 3) is an internal cover of the tire. Its main function is avoid any air leakage. In other words, it is an air sealant in all round section. The rubber which the liner is made is different from the tread and sidewalls. Usually, for liner this has a lower strength and elastic modulus, because it is a non-stressed area. However, it has a higher flexibility, which provides a good fatigue resistance, thus durability. The liner is compliant. All these properties comes from rubber with low cross-link density, because if these are too much, it means more voids which is not advisable for this application.

Bead and filler

The bead is a group of steel wires which are disposed in the region of the contact of the tire and the rim (Figure 4), its main function is to avoid the detachment of the tire from the rim. Around the beads there is a filler, that keep them fixed to the plies or chafer. As soon the inflation pressure increases, the tire bead tightly blocks any possible air bleeding between it and the rim.

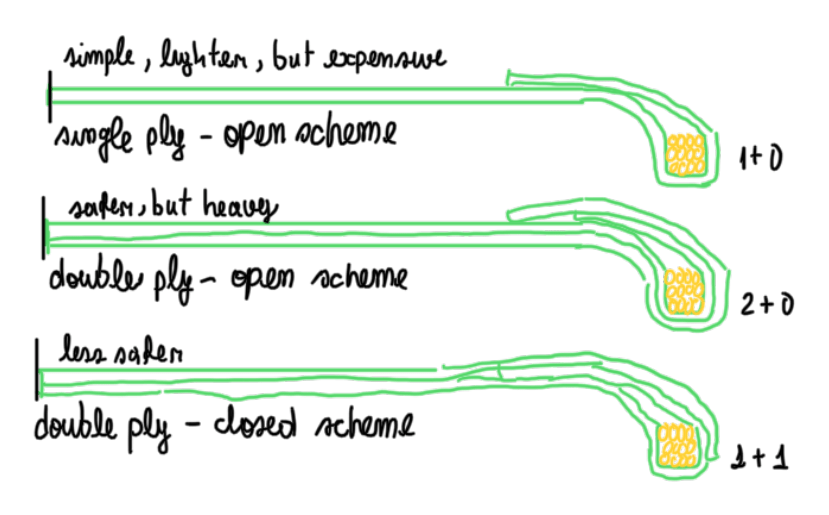

Beads are also part of the plies, which are around of it. The single play (Figure 5) is simpler, which means that is easy to manufacture and also lighter than the double ply types. However, this does not means that it is affordable, because the ply wire should compensate that is a single one with a stronger material, which could be more expensive. The other plies are safer than the single one, but the tire tends to be heavier.

Chafer and rim cushion

The rim cushion is the part of the tire rubber that adheres to the rim avoiding the slippage between tire and it. The chafer is layer of fabrics (steel) to protect the fibers against cuts and wear.

Wedges

This is the most critical part of the tire. Wedges (Figure 6) are the interface between the sidewalls and the tread. In cambered wheels, the tires exhibit a load concentration on the inner side. This region when under high lateral force tends to be detached. To avoid this some brands includes the so called wedges, which are not so common due to the cost increasing, but it provides a safer tire. In addition, wedges improve the fatigue resistance and prevents belt separation, because they are placed at both sides of the belts. This is done by joining together the edges of the belts.

References

- Haney, Paul. The Racing & High-Performance Tire – Using the Tires to Tune for Grip & Balance. TV Motorsports, SAE, January, 2003.