The two main competitions of endurance races are IMSA and WEC, both are based in different racing categories, gran touring (GT) and prototype. In IMSA, the prototype category is called GTP, while in WEC this is named hypercar (hyp). Since these two race together at 24 hours of LeMans race, they suffer a balance of performance (BoP) and GTP is renamed to lemans Daytona hybrid (LMDH), while hypercar is renamed to lemans hypercar (LMH). The main key performance indicator for an endurance racing team is:

- The driver;

- The tire;

- The car/product;

- The team manager.

There are three targets that endurance tires should reach. Races are very different when they are compared in terms of where they occurs. For instance, in Europe, the circuits have asphalts very well maintained and renewed. However, in US there are some tracks that still have the same asphalt since the track is created. Hence, these tracks have all the characteristics of an old asphalt, with many bumps and without an uniform grip. Hence, endurance tires must be built to deal with these conditions. For this reason, the main targets in tire design for endurance races are Safety, Longevity and Versatility.

Safety

An interesting fact about tire safety is that a tire never explode in low speed sections of the track, it always blow at the end of straight. Actually this is a point which the tire is most exposed to the forces due to speed. Although safety represents the drivers health and life, it also represent the tire brand name, since an accident caused by a tire failure also damages the supplier name and image.

Longevity

It is a parameter that in the endurance racing field is a performance one. For instance, the main objective of teams are double or triple stints with the same tires. In addition, depending of the event, if it is Le Mans or Daytona, the longevity can represent stay in the front for the maximum amount of laps without having many cars at the front. Since Le Mans is long track, a pit-stop to change tires can represent a car 1-2s faster, but even though the same is valid for Daytona, a pit-stop in this case can result in many cars separing you from the one which is really ahead of you.

Versatility

It means the choosing of the right tire to the right conditions, this means the tire compound and track temperature. For instance, the racing field usually uses two kinds of tires, the commercial and the confidential ones. Commercial tires have the same structure and technology of tire developed for road vehicles, thus there is no secret feature. Some racing series basically use tires from road cars. Confidential tires have structure which uses many technological secrets of the manufacturer. Usually these kinds of tires can be noticed, because commercial racing tires are harder than confidential ones, thus they require more negative camber. For instance, some cars from WTCC runs at 5° – 7° camber, while a GT car runs with 2° – 3°. These number can be lower if it is an open-wheels single seater, 1° – 2° negative camber.

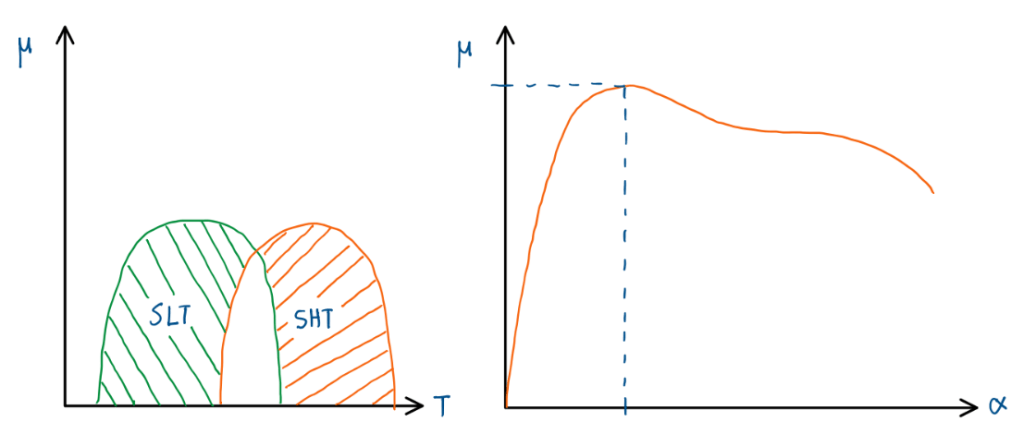

Design and development stages

Road car tires requirements are too wide, for instance, these deal with different environments. In addition there are also customer preferences, that use them in different situtations. On other hand, racing tires are much simpler in terms of customer requirements, actually there is only one, which is to make able for a race car runs as fast as possible. Usually in the main endurance racing series there are different tire suppliers and also different compounds. These are soft for low temperatures (SLT), soft for high temperatures (SHT) and medium for high temperature (MHT).

They are usually chosen for specific race tracks and the conditions at the event. The design and development states are based in four processes. These are basically manners to test tires previously to the race track test. This begins with a mathematical model which is developed with the properties and characteristics of the tire under development. Hence, this model is tested in a test-rig DIL, which means drive-in-a-loop, a virtual workspace or simulator. The reason of this stage is that it allows the test driver to subtract some KPI of the proposed model. These two stages are usually based in CAD design followed by FEA. Many teams and companies work with the Tame Tire software, this can also deploy the Tame Tire output on DIL. Hence, it is possible to have a preview, an estimate, of the car balance with the proposed tires. Actually, DIL is a tool which absolutely necessary for a race car or tire supplier. Drivers should trust in the tire model to extract as many informations she/he can. Although modern simulators delivers a closed to real response, sometimes they go far from the reality. However, it is a tool that delivers the trends or the main characteristics that the tire exhibit. This occurs because simulators has a great tolerance relative to tire replications. For instance, in a real track, if the driver goes out of the line, this usually result in, at least, an accident. In simulators are different, but tire models had improved a lot in a way that the results are continuously getting closer to the reality.

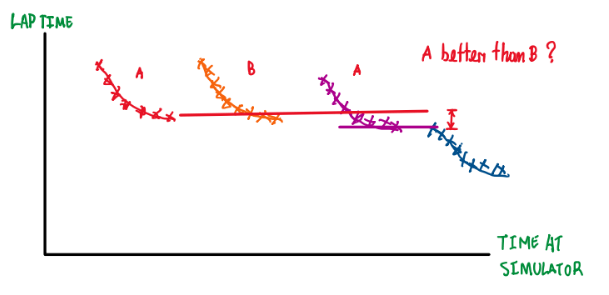

An important aspect of DIL is the test plan. Drivers usually get use of the simulator very fast. Hence, a strategy is usually to propose different tire models and car setups, then evaluate the gains. This makes able to visualize at which point the driver is getting use of the simulator, or when the tire model is being improved, or even if the car balance changes. Simulators must be identical to the race cars, for instance, its fidelity is not limited to the software alone. Actually all the simulator structure resembles a race car, for example, the internal package, the inside temperature, the smell and even the procedure to start are simulated. The tame tire is an empirical thermo mechanical tire model made exclusively for DIL applications. It allows to evaluate the belt stiffness, the contact patch distribution, the grip obtained by the tread and thermal evolution between tire layers. After the simulation and virtual stage, the first prototype are built and submitted to test rigs. These allow to evaluate tires in practical and real field according to their grip, thermal behavior, durability and longevity. Finally, the real track tests confirm the design from the numerical model and simulations. Hence, the target at the track test sessions are to understand the tire degradation in the real world. Track test makes able to understand if the tire is reliable even under debris. Another important point, that track test allows to evaluate, is if the front axles will do what is defined by the customer requirements, which was already simulated at DIL. For instance, if the car exhibits the best grip from the front and the rear axles, but these came at wrong time, thus this car can not explore its maximum grip. In these cars, may are better to have less grip but coming at right moment, this called car balance.

Tire mechanic

It is very important to understand that tires will not generate forces unless there are some relative movements between the tire and ground. This concept is valid for longitudinal and lateral movements. In this first case, the tire capability to generate forces is characterized by the slip ratio. It gives a metric of the difference of the speed seen by the wheel and the speed seen by the ground. Hence it is possible to describe the following assumptions:

- Kx = 0 → free rolling;

- Kx > 0 → acceleration;

- Kx < 0 → braking;

- Kx < -100 → locking.

In situations of lateral sliding, what characterize the tire grip is the slip angle α. This is the difference between the direction in which the wheel is pointing and the direction in which it is actually traveling. The relative speed together with the vertical load makes tire generates forces while adhere to the ground. As the tire rotates, the tread starts to be sheared until a point that the deformation make the tread element begin to slide. The tire still is at the linear condition.

Hence, it is possible to summarize that a tire when Fz is applied and a slip generated, lateral and longitudinal forces are produced. If sliding is introduced, the forces at the ground plan (x,y) can be generated. These can be measured by load cells and strain gages installed on the wishbone or push/pull rods. Since friction generates heat, the thermal behavior of the tire is strictly connected to the temperature at the tread. An important metric for a tire is the temperature window, which basically describe the tire sensitivity of the grip relative to the temperature. Usually on endurance racing there are different compounds for different temperatures, for instance, soft tire for high and low temperature. Another important point is the road roughness profile. Since each car generates different tire loads and relative speed, they face tracks differently. This occurs because tire grip generation is based on adhesion and indentation. The major part is generated by the adhesion. However, indentation is sensitive to roughness. Therefore, different tracks exhibit different levels of macroroughness and microroughness, that affects the grip level.

Tire key performance parameter indicators – KPI

The main tire performance key parameter indicators in endurance racing are pressure, temperature and degradation.

Pressure

Tire pressure is one of the main KPI when evaluating tire performance, it is usually measured by pressure gauges installed at the wheel valve or hand pressure gauges. Some of them also provides the air temperature measuring. Actually, air using in racing cause some issues. First it has a considerable humidity, then it can lead to vapor formation which affects tire pressure. In addition, air molecules are small, thus expose tires to diffusion, which is the reason why road tires often must be inflated. Racing tires are usually inflated with N2 (Nitrogen), because this compound has bigger molecules, thus less promptness to diffusion. In addition, due to its specific heat capacity and the lower vapor content, it is possible to provide more stable pressure conditions.

Degradation

It is the progressive loss of grip during tire operation. Even the tire sound during its operation changes. Tire sounds can change according to the components. Some of them are very noisy, or there are situations that they can be very silent. At highest grip, less noisy a tire will operate. Drivers do not need tire pressure or temperature, they usually look first for grip. Actually they are always looking for grip. They fell grip by the steering wheel, beside the self-aligning torque felt, they do not know how to distinguish the amount of it that comes from the mechanical or the pneumatic trail. Hence, the steering wheel can be a false sensor for the driver, but it is the only one. Tire degradation can be calculated by the lap time analysis. Since the fastest laps are always the focus, there is the degradation and some others outliers that affect laptimes. These last one can be traffic or slow laps, they should be filtered. Hence, the samples of laps that the driver is able to do will lead to a tendency, that allows to build a preview about the laptimes.

The overall car balance usually begins with a slightly understeering behavior. After some laps the car exhibits what is its overall balance, a light oversteering behavior, which it is manageable, and usually preferable, by drivers. When this increases too much into the oversteering behavior, the car became very difficult to control, very physical and stresses drivers a lot.

References

- Haney, Paul. The Racing & High-Performance Tire – Using the Tires to Tune for Grip & Balance. TV Motorsports, SAE, January, 2003;

- Part of this is article is based in my notes written during the workshop Tires In Endurance Racing given by M. Leschiutta and M. Angelelli at 01/12/2022 at Dallara Accademy.