A tire can be defined as a composite structure of a strong, light polymer fibers that held together in a matrix of viscoelastic polymers, rubbers. Specialized adhesives bond multiple components in a light, doughnut-shaped structure called, carcass. A flat band of rubber heat- and pressure-bonded onto the outside diameter of the carcass forms the traction surface, the tread. Reinforcing the carcass of a radial tire there are belts of polymers threads or steel wires. A relatively thin sidewall connects the tread to the steel cables in the bead area that clamp the tire onto the wheel. As can be seen, tires are made from a composite, a mix of different materials. In addition, they also require different manufacturing processes. Therefore, this article proposes a brief overview about the tire materials, specially rubber compounds, and its manufacturing processes.

Tire operates due to the slip angle α, which is the one between where the tire is pointed and where the car is actually traveling. α is generated, because rubber, an elastic material, yields an external force, resist movements with an opposing force, but it recovers to its original shape when the external force is removed. This effect is incremented by steel wires. Hence, it is possible for a tire to point for a different direction from the one which the car is actually traveling. As the tread is touching the ground, it generates grip. This begins from the leading edge and, as the tire rolls, each small increment of tread in contact to the ground sits down a small distance towards the direction which the tire is pointed. In addiction, due to the car weight on these increments, the tire sticks on the road. Therefore, the tire tread generates forces which are transmitted to wheels and suspensions.

Tires deforms as it rotates, thus the section in contact with ground changes its shape, but recover to the original one when it is leaving the ground. The force needed to deform a tire is what produces the lateral force. This is one of the main tire characteristics, or rather, a rubber one. Actually, tires are not only made from rubber, there are many compounds on it. Hence, it is important to approach more deeply the rubber.

Rubber

Rubber is a long chain of macromolecules called, polymers. These are made by many molecules of monomers. Hence, a natural rubber (NR), latex, is a mixture of monomers. The main one is the isoprene and latex, this last is polyisoprene polymer.

It is possible to link two polyisoprene through sulfur bonds. These chains lie close to another, thus a chemical bond occurs, this is called crosslinks. The characteristics of these chains change according to the type of the polymers and if other materials are used. Since crosslinks do not form espontaneously, they require heating to achieve it. This is called vulcanization and have a proper time, temperature and pressure. This process creates entanglements and crosslinks that change rubber features from sticky to a heat and tensile resistant rubber.

Elasticity and viscoelasticity

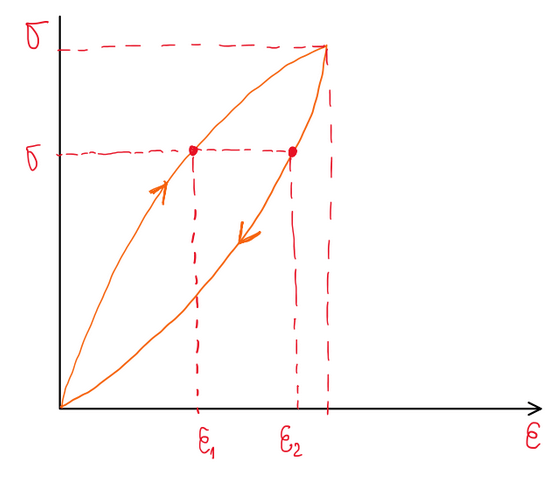

Rubber is defined as a viscoelastic material, because there are viscous effects that interfere on the stress and strain relationship of this material. Any elastic material has the feature to distort and return to its original condition. Part of the stress during relief does not return to the stand-by condition (Figure 5), it is converted to heat. In rubber this process occurs due to the viscous effects. Part of the stress during relief does not return to the stand-by condition, it is converted to heat. In rubber this process occurs due to the viscous effects.

Creep test

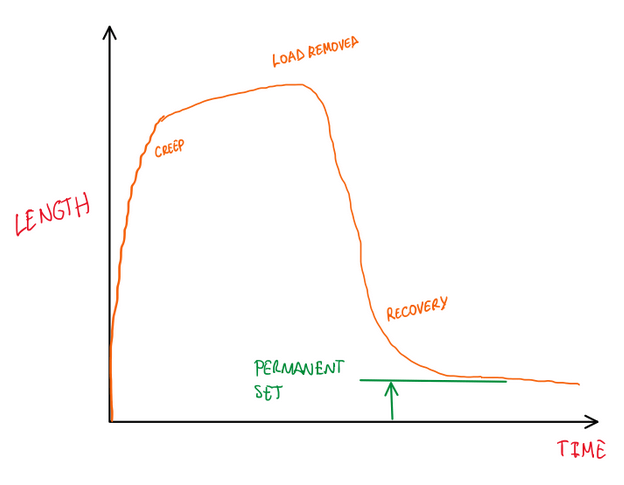

When a mass is hanged to a rubber piece, the distortion seen reflects the hysteresis. At first moment it deforms very quickly, but its rate reduces to a point that the deformation occurs slowly. When the mass is removed, the rubber rapidly returns to its original condition, but it does not return completely. Instead, it becomes slightly stretched relative to its initial condition. This is called, creep and occurs due to the loose, three-dimensional network formed by polymer chains. These slide between each other and they can change their shape during this process. The viscous effect comes from these interactions between chains. The crosslinks are the points of limit for this deformation, which means that at some point a load can break those crosslinks, thus avoiding the complete recovery.

Mechanical model for rubbers

The rubber mechanical model is based in two springs in series, but one of these is parallel with a damper. This is the viscoelastic part of a spring. A cyclic force at the point A generates a deformation which is mostly governed by the spring effect. In other words, the force applied is gave back at almost the same intensity. This is the point which the damper effect occurs, because dampers are sensitive to speed, thus the frequency which the force is applied. The viscoelastic effect occurs due to the movement of the chain molecules, when this is a faster than their usual allowed mobility, the rubber stiffens resisting to the movement. On the other hand, when the deformation occurs at lower rate than usual, the chain molecules have more time to move and the viscous effect is lower, thus less resistance.

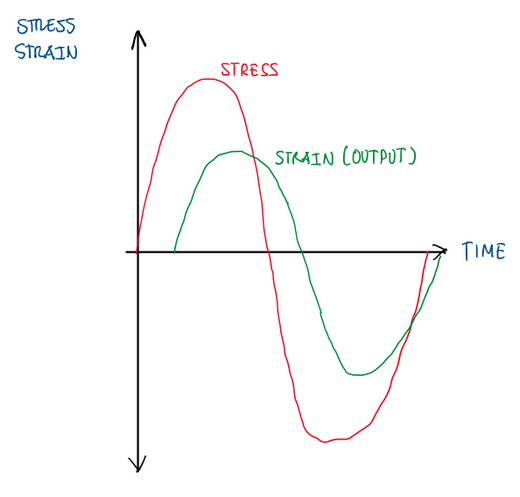

The stress represents the cyclic force input at the point A and the strain curve is the output at the point B. Hence, the viscous elastic effect damps part of the movement, which is the reason that the response occurs in a lower intensity and lagged in time. This also represents an energy loss, which is called hysteresis and a temperature increasing of the rubber. If the force is increased, the rubber will be deformed more quickly, the opposite is true. In addition, a constant force can be applied and its frequency can be varied according to the situation. If this condition is monitored, it is possible to observe that the viscoelastic system deforms accordingly to the frequency of disturbance.

Glass transition temperature

As many engineering materials, rubbers also have a behavior variation according to the temperature. Basically, as the temperature decreases, the mobility of the chain molecules also decreases. However, before this condition occurs there is a threshold, the glass transition temperature, Tg. Below this, the rubber chain molecules loose their mobility. Usually Tg varies from -250 to 100 °F for some silicone and polystyrene rubbers, respectively.

Rubber compound for race tires

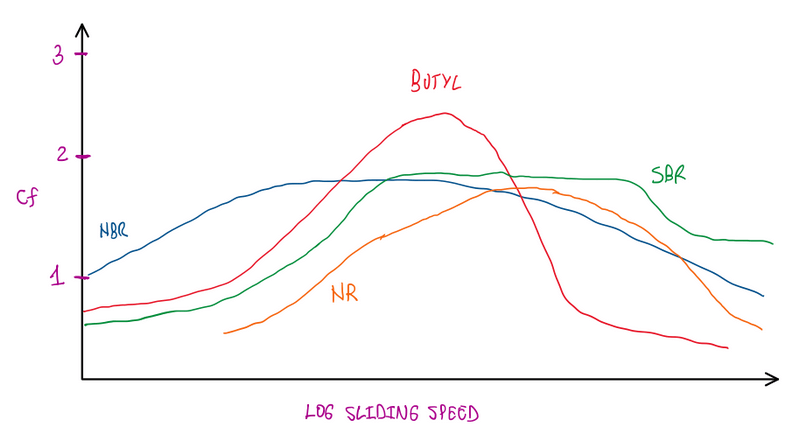

Figure 9 illustrates a sliding test made with different types of rubber. These are the natural rubber NR, the polyisobutyline (Butyl), the styrene butadiene SBR. As can be seen, each of them exhibit a different range of Cf according to the sliding speed. The maximum Cf is just one of the criteria when elaborating a tire compound. Actually, there is also the level of the rubber hysteresis, which is measured by a rebound test. As higher the rebound is, lower is the hysteresis, thus lower the grip. However, this kind of rubber is more resistant to wear and results in less rolling resistance. Therefore, it is possible to notice that a tire recipe has no standard, instead, it tries to deliver the customer requirement.

Tire recipe

The main tire components are the rubber, oil, fillers, softeners, vulcanization and chemical additives. The rubber is one of the heaviest parts, it can be composed by single polymers or a blend of them. The filler is composed by carbon black and silicas. It can have other specific materials that are added according to the demand. Softeners are components that improves the elasticity of the chains. The vulcanization additives are included to adjust the vulcanization rate, usually sulfur and zinc oxide are used. Antioxidant and antizonants are other additives that improve the manufacturing process and the tire life cycle. Usually, stiffness and hardness of the tire compound is defined by the amount of carbon black, oil and softeners. In addition, there is the rate which the vulcanization process occurs. This defines the crosslinks formations during the process. The type of carbon also helps to improve the final product of the vulcanization. There are two types of SBR, the synthetic rubber and the styrene butadiene copolymer.

Carbon black

The carbon black are divided in easy processing channel black EPC, low-structure high abrasion furnace black HAFF, high abrasion furnace black HAF and the fine furnace black FF. Carbon black is the main tire compound, its amount and composition is a proprietary information of the tire manufacturers and is not usually known. They are mixed with rubber in the Bambury mixers. These are a kind of magic filler, because they not only improves viscous forces, but also hardness, tensile strength, tear strength and road wear properties. This occurs, because carbon black has a structure that also have chains of molecules, which when combined with rubber, became entangled and increase the amount of crosslinks, most of them by inter bonded chains. As a result, the tire compound has a higher viscoelastic effects and strength.

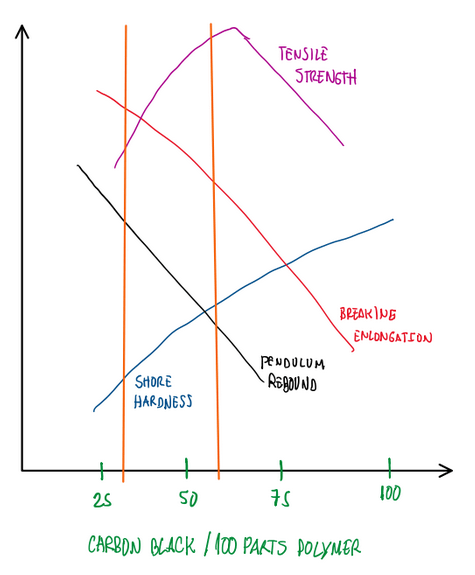

Figure 10 illustrates the main parameters evaluated after carbon black addition. As can be noticed, there is no standard amount of carbon black. An exagerated amount of it can result in some loss of features. For instance, tensile strength and enlongation. The rubber can also be excessively hard and hysteretic. The problem with carbon black is that it improves the electrical conductivity of the tire. Another important compound used in the tire recipe is silica, more precisely, silicon oxide, SiO2. It improves the rolling resistance, tread wear and traction tire capability in wet conditions. In addition, Si is not electrically conductive as carbon black. The usual proportion of Si and carbon black is 25/75 and 50/50.

Vulcanization

A Figura 10 ilustra os principais parâmetros avaliados após a adição de negro de fumo. Como pode ser notado, não existe uma quantidade padrão de negro de fumo. Uma quantidade exagerada pode resultar em alguma perda de características. Por exemplo, resistência à tração e alongamento. A borracha também pode ser excessivamente dura e histerética. O problema com o negro de fumo é que ele melhora a condutividade elétrica do pneu. Outro importante composto utilizado na receita do pneu é a sílica, mais precisamente, o óxido de silício, SiO2. Melhora a resistência ao rolamento, desgaste do piso e capacidade de tração do pneu em condições molhadas. Além disso, o Si não é eletricamente condutor como o negro de fumo. A proporção usual de Si e negro de fumo é 25/75 e 50/50.

Manufacturing process of tires

The tire manufacturing is based in the following activities:

- Mixing;

- Tread extrusion and taping;

- Tread calendering (Rubberizing);

- Building;

- Curing.

Mixing

The rubber mixing is based in the Banbury machine. Inside this one there are Banbury rotors (Figure 11). Through the gap of these, the rubber is mixed and heated. The rotor are heat treated. The rubber goes out of the rotors hot and creamy. The Banbury machine mixes different rubber compounds. The temperature must be controlled, so as the speed. A faster process results in a lower rubber viscosity.

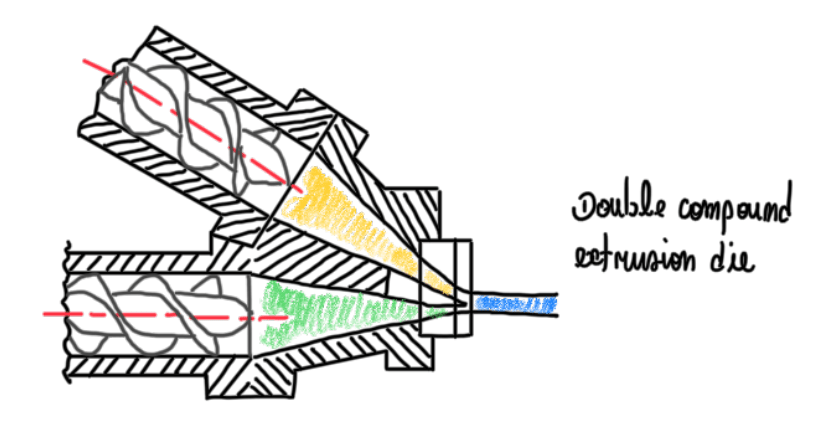

Tread extrusion and taping

The rubber extrusion is a process performed just after the rubber mixing. The critical point is the different glass temperature, Tg of the polymers. In this process the temperature is controlled by the speed of the machine. The main concern is the viscosity, which is temperature dependent. If the process is fast, the rubber temperature will be high, thus the viscosity will be reduced. Hence a process focused in high production usually results in low viscosity rubber, which is bad for grip. Therefore, the production of racing and production tires are different. The first is usually slow to allow a lower Tg and preserve the rubber viscosity.

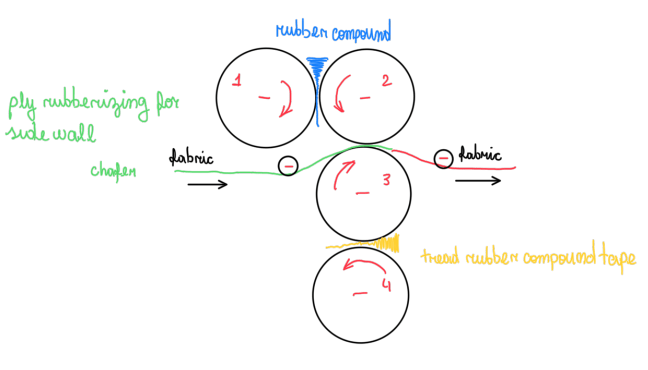

Tread and ply calendering

The rubber compound is added to rubberize the plies and make the sidewalls. In the case of the tread, only rubber compound is added. There are different calendering lines for the tread, the plies and the belts (Figure 13). After caledenring, the rubber taping process is performed. This is one of the lasts stages of the tread production.

Cord cutting

The laser cutting process make cords with diagonal cuttings. Radial tires are not totally 90 ̊ fibered, there is a little slope in the cord orientation. This is defined at this stage, which is called cord cutting. This process cut the plies in the desired shape. A very fast method is to use carbon and composite frames to provide lightness and speed.

Tire building

After the cord cutting, the next process is the tire building. The first part is the tire lay-up. Once the rubber and metallic structure are in the mold, the shape of the what will be the tire is called green tire. Moreover, a conforming machine deforms the green tire to form the real tire shape. The main problem with this process is that there is no guarantee that these components will be kept in their positions during conformation. Usually they don’t. Squeezing of the green tire and then conform it in more narrow structure is a way to reduce this effect. However, still has no repeatability due to the natural behavior of the rubber and the composite materials. For instance, there is no guarantee that the wedges will stay at the same place during the process. There is a relative movement between the inner components. The difficulty is due to the different rubber compounds and the non-isotopic characteristics of the rubber. Another critical point is to connect the inner liner and the plies together, because a gap or a junction are not allowed. The first, because will result in a catastrophic failure, while the junction is not possible due to the characteristics of those components. Hence a filler is used to connect and make them joined.

Curing – Vulcanization

The tensile strength is a function of the fibers, but also of the resin, in other words, the rubber compound properties. For instance, in a racing tire, the curing is usually faster, because is interesting to hold a very high hysteresis. However, the tensile strength is usually obtained from the fibers, which can be Kevlar (aramid) or steel fibers. Steel wires alone are not cured, but the rubber involving them is. Finally, after the conformation the vulcanization or curing process occurs, which is performed on the curing chamber. This is divided in two halves, they are closed together during cure time. The two halves are the molds which defines the tread shape, they are usually made by aluminum or steel. The first provides a faster process, cooling and heating, but also more mold expansion which should be controlled. The steel molds are better for high production batches due to its consistency. However, to guarantee the contact of the rubber with the mold, a high inflation pressure must be guaranted. During curing the different rubber compounds do not mix, because they have a different Tg. Hence they cure at different temperature which avoid mixing themselves. The contact between the tread and the mold generates a high friction which could generates some inconsistencies on the tread dimensions. Hence, some lubricants are applied in the mold to reduce friction and improve the quality. Major part of the lubricants are water based, because the oil based ones are temperature dependent.

References

- Haney, Paul. The Racing & High-Performance Tire – Using the Tires to Tune for Grip & Balance. TV Motorsports, SAE, January, 2003.