Handling systems are necessary to provide movements of the suspensions in order to emulate the vehicle behaviors. These are braking, acceleration, high speed corner, slow speed corners and straight line movement. Hence, it is possible to change the ride heights and steering. In addition, the movements yaw and rolling are also performed by the wind tunnel model (WTM).

Types of actuators

Any WTM has handling systems to execute the vehicle movements, but these systems can differ according to the technology level of WTM. There are three kinds of actuators, the linear servo, the linear hydraulic and hexapod actuator.

Linear servo actuators

The linear servo actuators control roll and pitch, thus there are more than one actuator inside WTM. In addition there is also one for heave and for yaw movements. The actuators are step motors and do not perform a long stroke, which do not allow extreme positions of the wind tunnel model. In addition, these are housed inside WTM and requires a brake to hold them under position. This occurs, because the displacement requested is translated into rotation and when the requested position is achieved, the motor is de-activated and could rotate backwards. Hence, it is applied some brakes.

Linear hydraulic actuators

The linear hydraulics actuators (Figure 2) are useful when the wind tunnel model is too tight to accommodate the actuators. They are usually mounted separately in columns with an aerodynamic shape to not disturb the air flow. The hydraulic actuators are mainly used for heave and pitch movements. When these movements are allowed, two hydraulic motors are used, one at each axle. Actually, the columns are called stings. Hydraulic motors allow high loads, strokes and handling speeds. However, the oil is sensitive to temperature variations, the hydraulic system is more complex and has to be coupled with the rolling system. Usually, wind tunnel with hydraulic systems has a combination of these with the linear servo actuators. Hydraulics control pitch and heave, while linear servo controls roll and yaw.

Hexapod

The hexapod is a system that concentrates several actuators, thus it can reproduce each movement of the car on the wind tunnel model. The hexapod or Stewart Platform (Figure 3) is derived from the dynamic simulator handling systems. It is a very precise system that has its costs, which is the most expensive of the three systems. However, it is the most precise. These features justify its adoption in the most used wind tunnel handling system at Formula One. Another important feature of this system is that WTM is not requested in terms of internal room, but the sting follows the model and this results in a lower mobility in terms of yaw.

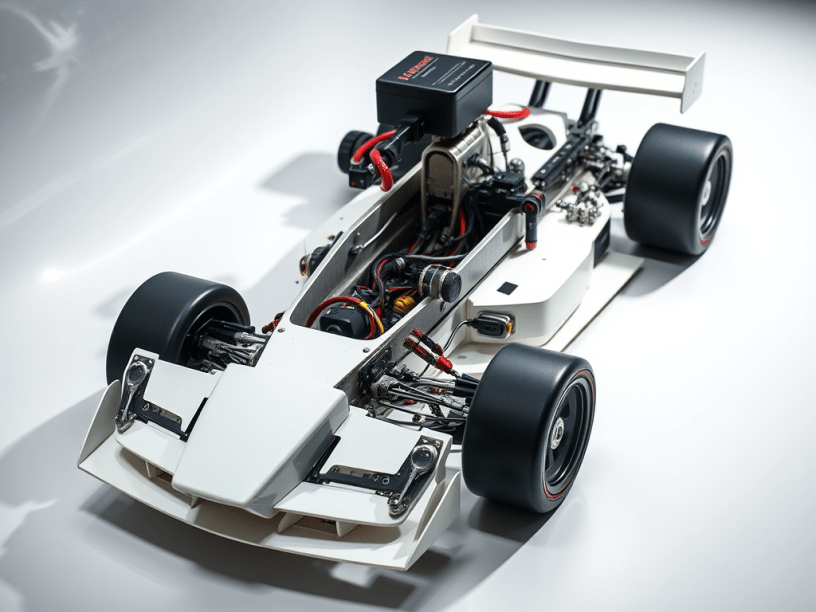

Wind tunnel model systems

Since the wind tunnel model is a scale replica of a real car or race car, some systems of these must be included, because to build the aero maps it is requested the variation of WTM position. This is performed by several systems that control suspensions, steering and tire pressure.

Steering system

The steering system (Figure 4) is part of the handling ones since for open wheels race cars the aerodynamics is affected by them. A step motor is assembled just to control the steering arm. Actually, there is a separated system just for this function. Usually step motors are precise enough for this application, but it requires a precise tolerance from the steering components.

Active suspension system

Another handling system is the active suspension. Since open wheel cars are sensitive to the wheel shape under the flow, an active suspension is useful to apply loads over the wheels in order to cause a deformation of the tire contact patch. It is important to understand that neither all WTM have pneumatic tires. Actually, some of them are equipped with rigid tires. In these cases there is no active suspension. The step motor, when activated, pushes the push-rod that applies a force on the wheel and against the ground. Active suspensions have a huge impact on WTM so that there are different levels of them, the low and the high level wind tunnel models. Their difference is the degree of fidelity to the real condition. For example, high level WTM have pneumatic tires, active suspensions and, in some cases, active tire pressure systems. Conversely, low level WTM usually have simpler suspensions and rigid tires. Most of these cases are high performance cars and low budget race cars. As can be seen, only high level wind tunnel models are equipped with active suspensions.

Feedback system

The feedback system collect the position of the actuators and the model body. These two are measured by potentiometers and lasers, respectively. The problem is when the position of the actuators is quite different from the position of the model. These do not fit, because the connection between the model and the wheels are not rigid, there are some compliances. Although these deformations are less than one millimeter, it is necessary to measure the position of the model in a very precise way. For this reason, the feedback of the model is kept by lasers. Hence, it is measured the actuator and model positions. The first, if the difference between these measures increase, the system can stop. Hence, it helps if the laser is not working, thus avoiding the model to have any contact with the ground. The feedback on the model is required by regulations. Actually, the model height can be measured by the push-rod actuators, since these are part of the suspension mechanism, it is possible to apply geometrical and mechanical equations. However, these are not precise and they are a source of errors.

Feedback control

The feedback control is based in two techniques, the standard and the continuous control techniques. The standard control is based in an iterative process. This begins with the definition of the nominal value. Then it is calculated a correlation based on the actuators feedbacks. A new nominal position is defined based on those feedbacks. This process is repeated until the feedbacks lie within the accepted tolerances. Usually, these variates are between 0.05 and 0.1 mm. The standard control technique is a bit long due to the iteration, but it is functional. The continuous control technique applies a correction during the measure. For this reason, it is called dynamic correction. Although it is more complex than the standard control technique, it is more precise and faster in terms of handling. This is possible, because the calculation process is not interrupted by the calculation of the difference between the position required relative to the actual position.

Data acquisition systems

For all data produced in just one wind tunnel test, it is required a proper acquisition system. This registers the information captured by the feedback systems. Hence, suspensions, steering, active exhausts, air temperature, tire pressure and temperature are the main data stored in the acquisition systems. The data registered by load cells and lasers are forces and displacements, respectively. There are two types of acquisition systems, discrete and continuous.

The discrete acquisition is based in the movement of the model, thus a short waiting time is performed in order to allow the stabilization of the flow field. The registration of the data only occurs in the one defined in the aero map (Figure 8) previous the wind tunnel test. On the other hand, continuous system performs the variation and the registration at the same time. The displacement path of the aero map is defined previously.

References

- This article is based on the lecture notes written by the author during the Industrial Aerodynamic lectures at Dallara Academy.