The objective of the embodiment design is to define the overall layout, to determine the preliminary form for any important component of the layout, to determine the production processes and to provide solutions for any auxiliary functions. An important aspect of these objectives is that, these are not a sequence or punctual actions, instead it is a loop of actions, but this accepts the input of results that come from others or prior researchers. This is an approach very common into the automotive industry, it is called carry over, which is when any existing solution is applied in a different product proposal.

The main point into the embodiment design is the identification of the priority, that should be followed by analyzing the different subsystems of the solution. Considering again the example of the hub-shaft connection. The variant 2 was selected as the best option. Hence, analyzing this variant again, it is possible to notice that the most important part is difficult to be defined. Actually, what is really important is to define the part that has the highest priority for the development. In situations like this one, a good approach is focusing on the main function of the system. In the case mentioned, the main function is the test rate between hub and shaft connections with an impulse load. Hence, the priority is the capability to produce the condition that is requested to measure, thus the cylinder cam and the lever maybe are the most important components of the variant 2. In the second place, it could be from the step motor, because its technical characteristics define if these are enough to realize this test.

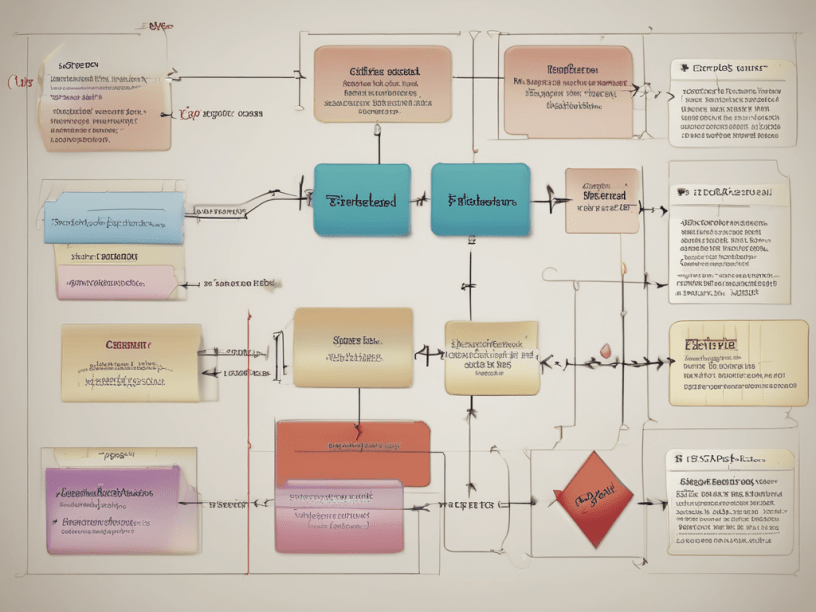

Embodiment design flowchart

The embodiment design can be a procedure as the one illustrated at Figure 2. It can be divided in two parts. The first one is, assigning the technical department and this one delivers a layout called, preliminary layout. Actually, this is a final layout, but not optimized. The second part is about validation, the optimization, the calculation of the most important component. It is possible to notice that this is basically a division in two job profiles, the designer and the analyst. The first one prepares the overall layout of the solution, the dimension the components, the bill of material and the overall cost of the solution. The analyst very often uses the simulation tools, CFD and FEM, thus they go deeply into the dimensioning of a specific component. Usually, this is the one with the highest priority one. They feedback the designer about the optimization. Figure 2 illustrates that, during the first part there are two different levels, the first one is the feasibility analysis of a solution, while the second part is the design analysis.

The feasibility studying verifies if the solution is feasible with respect to the overall layout defined at the beginning of the design process. During the design part it is selected the component, the material and the loop that have to be closed. Actually, the process is a loop between the two parts. Normally, companies adopt a concurrent engineering for the part and system design. This means that, these processes are not realized one after the other, instead these are performed in parallel. Hence, returning to previous steps to update them is part of the process. This is the main reason why computer aided tools are so important. These allow to change parameters, dimensions and calculations in a very fast way. Therefore, the parametric approach or the model based design of parts and systems is a crucial part of the design process. The feasibility study has three objectives, the size, the assembling and the material determining requirements. The geometry and the material should be considered together with the overall assembly of parts in order to understand the overall size, the feasibility of the system and to have a rough information about the cost of the part. It is possible to produce a description of any spatial constraint for the system in order to arrange different parts together.

Reference

- K.T. Ulrich, S.D. Eppinger, Product Design and development, Mcgraw-Hill, 2019;

- G. Pahl, W. Beitz, J. Feldhusen, K.H. Grote. Engineering Design – A Systematic Approach. Springer, 2007.