In order to manufacture a component, it is found parts that are attached by adhesive. In addition, some inserts that are present in monocoques and chassis can be considered as components that are attached by adhesive bonding. Therefore, there are two techniques regarding the adhesive use. The first is an important technique for the composite materials, specially in cases of joining them together with another material. For instance, joining a polymer with a metal. Nevertheless, adhesive joining is not the only method to join composites. Actually, there are also very well known method as fastening, thus rivets or bolts can be applied in some cases. These are not often considered for composites, because to have a bolt connecting two parts it is necessary to drill a hole through them. This increase the chance for damaging due to the manufacturing. In most of these, there are left free edges from where the delamination can start. Therefore, fastening techniques in which it is necessary to drill a hole on the composite should be avoided whenever is possible. In addition, mechanical fastener joints tend to use the available material inefficiently, because the transmission of loads by bolts or rivets is very local. Hence, there is a significative stress concentration around the bolt and the remaining adjacent part are quite little loaded. The adhesive bonding instead, acts on a large surface and can distributes loads better than fastening. However, mechanical fastening might not be completely avoided, because most of the applications require to disassembly the components. Adhesive joining must be considered as a permanent bonding, like welding for instance. To disassemble a component mounted through an adhesive joint it is necessary to heat-up the adhesive region above its decomposition temperature. This is very time consuming. Then, mechanical joining must be used in cases which easy maintenance is not a relevant requirement. From the point of view of fail safe condition, which means safe way of the component failure, adhesive joints miss a property of structure redundancy. This is an approach that provides a progressive path until the collapse of the structure. In other words, the failure is not subtle. For instance, the failure of a simple attachment point does not cause the entire structure collapse. However, in the case of adhesive joints, the situation is different. When a damage can develop along the structure, the adhesive layer provides no redundancy. In the case of fasteners, even though one of them breaks, then the loads are re-distributed through the other fasteners. This is the reason why mechanical fasteners are still preferred in the aeronautic field. On the other hand, bonding joints are usually used in small aircrafts, which the requirements are less restringing regarding fail safe condition. In the case of race and high performance cars, the fail safe condition is not highly required, thus the use of adhesive bonds are preferred. The main impact of adhesive joints is the weight reduction since fasteners are eliminated. The ones used for race cars are usually made by titanium, high strength steel and, in some cases, aluminium. This means that, they bring weight into the structure. Therefore, in lightweight structures, adhesive joining is an elective technique.

Adhesive definition

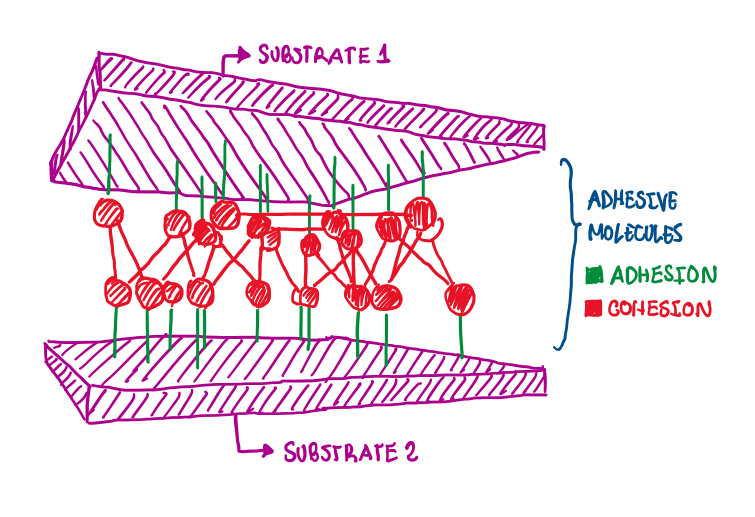

The definition of adhesive is sometimes wrongly described, because it is named as resins. This is not correct, because even though an epoxy adhesive has the same base of the epoxy resin, its formulation is rather different. Typically it has some fillers, toughening and bonding agents that have the ability to develop a good cohesion and adhesion. Hence, there are two properties, that have to be developed in a good adhesive joint. These are ones concerning the structure of the adhesive and concerning the interface with the subtract. This is the weakest point of an adhesive joint, because the interface is much more difficult to control than its properties.

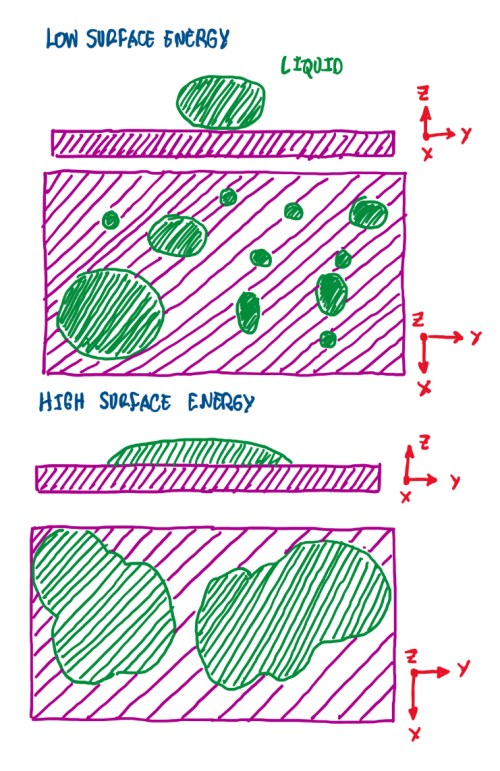

However, there is a proper parameter for this control, the wet-ability of the surface. This is an empirical measure of the surface energy. Hence, the lower the surface energy, the lower the wet-ability, thus the lower the adhesion. In the case of high surface energy, then the wet-ability is improved, thus the adhesion is better. Generally, metallic materials have an approximately high surface energy. Hence, they exhibit a good adhesion for adhesive joint. For some polymers, the surface energy is high, but there is a large number of them that have a low surface energy. Therefore, in these cases will be much more difficult to obtain a good performance of the bonded joint, unless it is used specific surface preparation.

Surface preparation

There are some methods to improve the surface, these can be by hydrophysical means, like plasma or laser treatments, or by chemical means. These can be through the use of adhesion promoters or primers, that are chemical agents related to the surface before bonding. They have a good adhesion to the substrate and to the adhesive. Hence, they are an intermediate layer that works well with the adhering material and the adhesive. In some metals it is also necessary some surface treatment. For instance, in aluminum alloys or stainless steel cases, it is obtained a better performance if it is made some chemical treatments before, which is the acid etching. Actually, these two materials have a protective oxide layer on the surface, which prevents a good adhesion. Then, for those materials, it is necessary to remove the oxide layer before bonding.

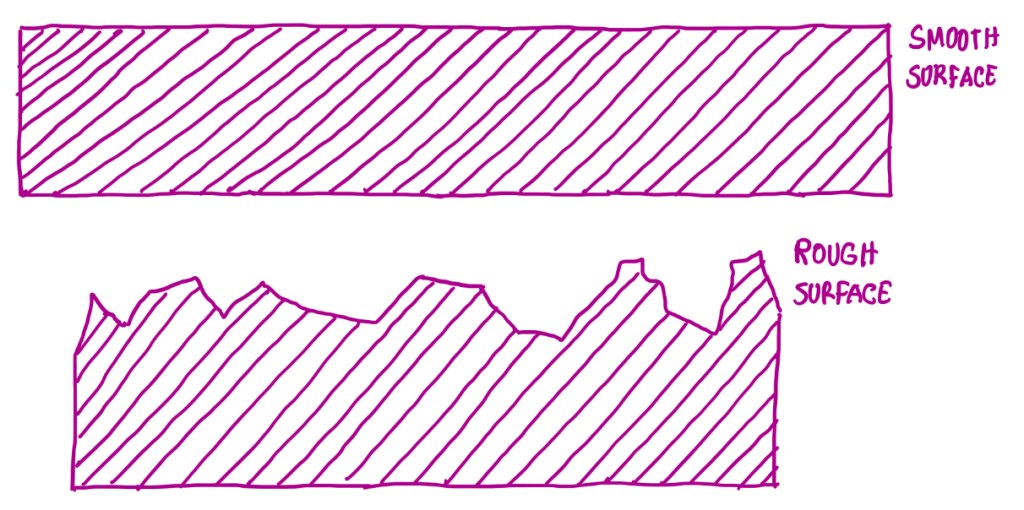

The oxide layer can be removed mechanically, by grinding or sand blasting. However, the mechanical etching is a better approach in order to have a surface layer that shows a better adhesion than the original oxide layer. In any case, the rough surface is a process that the surface roughness is increased by grinding or sand blasting. The reason is to provide more grip in terms of both, the real region surface, which is higher since the length or area of the surface is higher than the smooth condition, and the rough surface. When these are matched, it is performed the mechanical interlocking of the adhesive. Another step of the bonding is to put adherents into contact by some pressure.

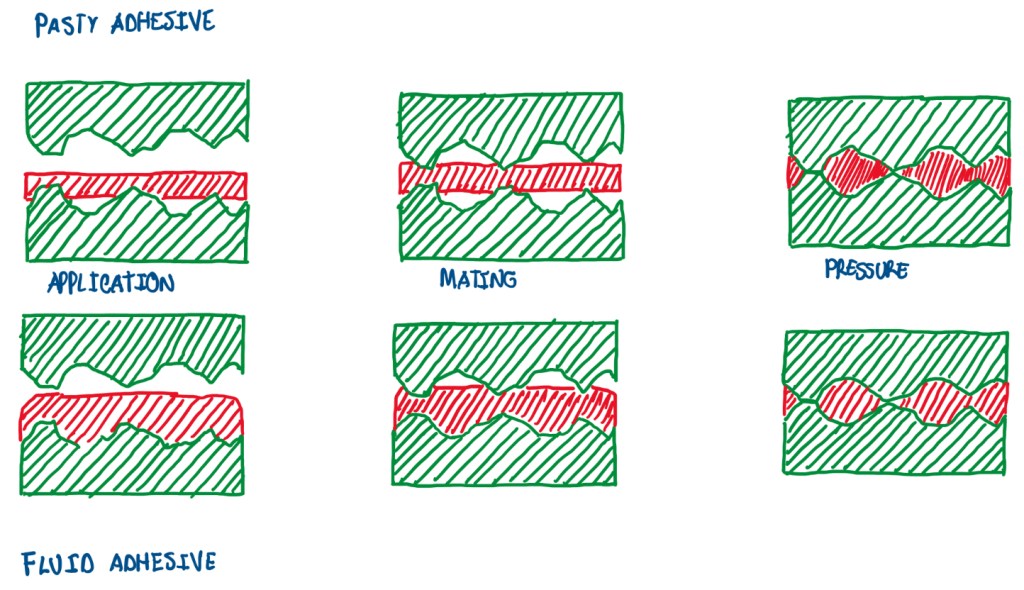

There are cases in which the adhesive layer has a prescribed thickness. The reason is that, some cases require a high precision from the joints. If the adhesive thickness is not controlled and the adherents are just pressed, the surfaces would be in contact in some point, but would have no contact in other points. This penalises the strength of the joint. For this reason, there are cases which the adhesive thickness are prescribed. However, general industrial applications are not feasible to use those kind of adhesives. Hence, to have an uniform adhesive in those cases, it is necessary to add small glass fibers or spheres into the adhesive. In the moment of pressing, these will provide a bond line which is limited in thickness by the size of those wires or spheres. The adhesive can be fluid or pasty ones. The first is very good to spread all over the surface. However, due to its low viscosity, it becomes very difficult to be applied in vertical surfaces. For these cases, a pasty adhesive is suggested. This is also named thixotropic adhesive, which means that is necessary to have a certain shear force in order to make then flow.

Adhesive joint failure modes

To evaluate if an adhesive joint is good or not, its failure should be analyzed. There are four basic modes of failure, the adhesive, the cohesive, the mixed and the substrate delamination one. The adhesive failure occurs at the interface. This suggests that the adhesive joint is not good, because the adhesion forces are lower than the cohesion ones. Then the maximum possible strength is not reached. This is the adhesive failure. On the other hand, when the maximum possible strength is reached, the failure is the cohesive one. In some cases there are manufacturing conditions that will not reach this kind of failure.

Another kind of failure is the mixed one, or adhesive/cohesive failure. In this case, there are regions under adhesive and cohesive failures. This means that, the two strengths are not far from each other and the failure occurred at almost the maximum possible strength of the joint. Locally differences on those strengths is what determines the failure path. The substrate delamination occurs when, there is a small region at the beginning where the propagation of the crack has started. Usually, this region has lower resistance with respect to the adhesive layer. Then the delamination starts. This is a quite common mode of failure in composite materials.

Adhesive Classification

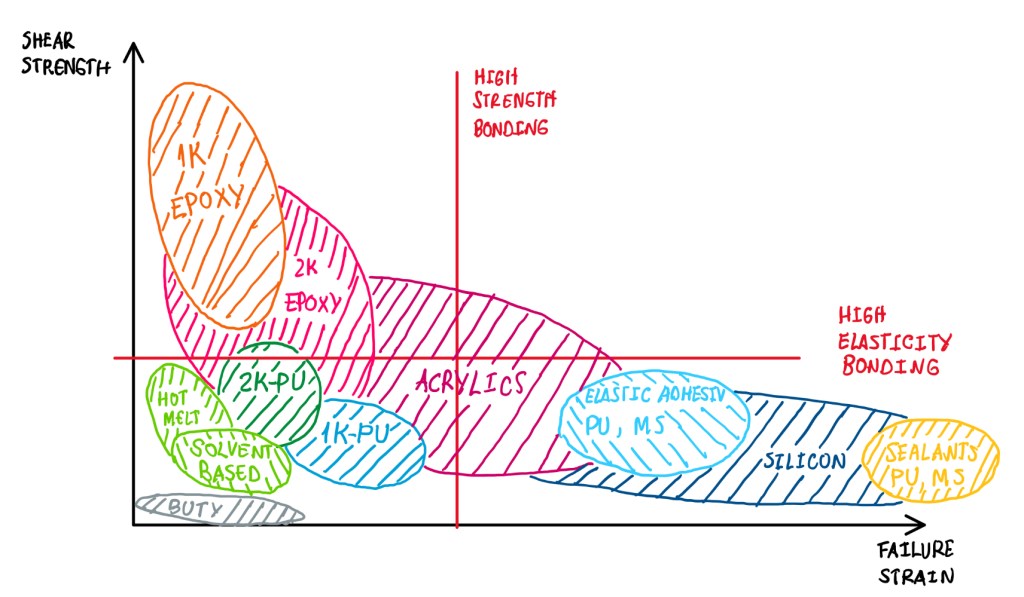

The nature of an adhesive is its base polymer and the performance provided by it. A diagram correlates shear strength and failure strain. It is divided into four quadrants. The one that corresponds to a high strength and low-medium intermediate failure strain, is the one represented by structural bonding. A quadrant that locates the low strength and high failure strain cases describes a high elasticity bonding. For instance, the polyurethane adhesive for glass fibers and metals, as in the SUV Ford-Troller. If the structural bonding is used to obtain a high strength connection, the high elasticity bonding is used to obtain a high compliance connection. For instance, when the material of strongly different thermal expansion are used, the elastic adhesive can compensate this difference more easily with respect than a structural adhesive. This one is stiffer, but less tolerant in situations like that.

Design fundamental rules

The design of components that will be bonded should follows some rules. These are considered since the scratch of the component is proposed. There are two fundamentals requirements, the first is to maximize the bonding surface and to minimize the peel/cleavage stresses. These are a sort of opening type of stress when there is a more rigid adherence. A good bonding area may provide an even distribution over the layer under stress.

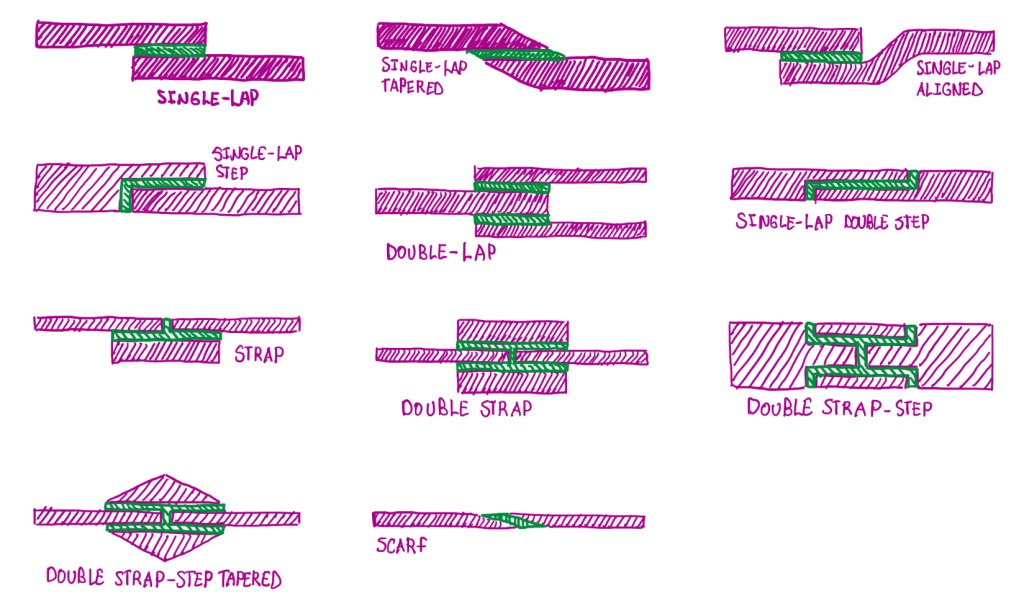

Adhesive bonding works well in any type of overlap joints, because they have minimal stresses and they allow to maximize the surfaces as large as possible. However, maximize the bonding surface means that, the butt connections will be avoided. If for some reason the butt connection still is used due to dimensional or aesthetic reasons, the scarf joint should be used. In this case, the area of the connection is not perpendicular to the load direction.

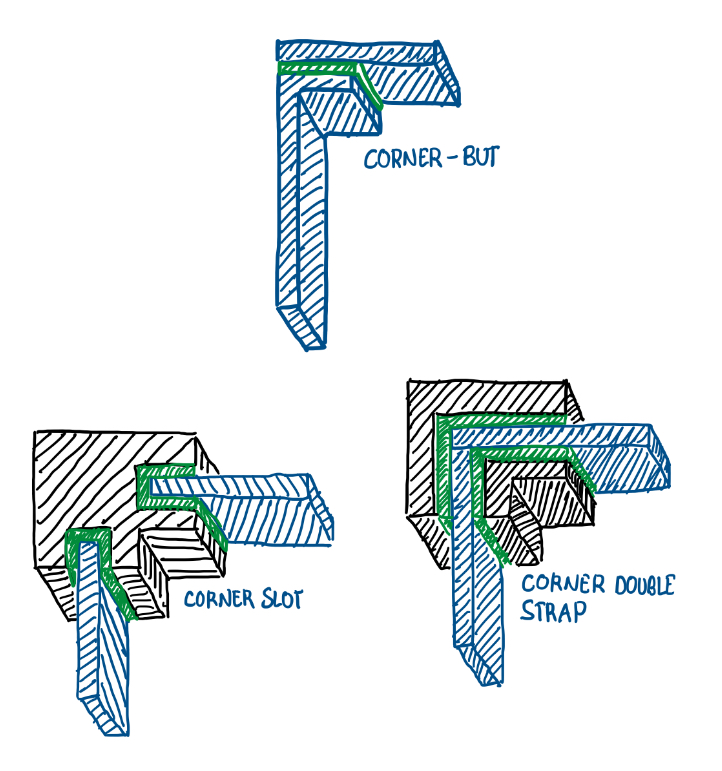

In the case of non-planar joints, there is the option of a corner joint. However, it is not possible to join at the corner. The solution for that is increasing the bonding surface by using a L-shaped adherent, a corner double strap geometry or a corner slot. This last one is called structural load, which is a block of material that is machined in order to provide slots. These keep the adhesive and the adherent together. The cylindrical joints are divided in five variations, bevelled, sleeved, bevelled tube and shaft, parallel shaft and tapered shaft. Most of them are solutions to avoid a bonding surface perpendicular to the cylinder axis. In addition, some variations take advantage of a tailored angle between tubes and shafts.

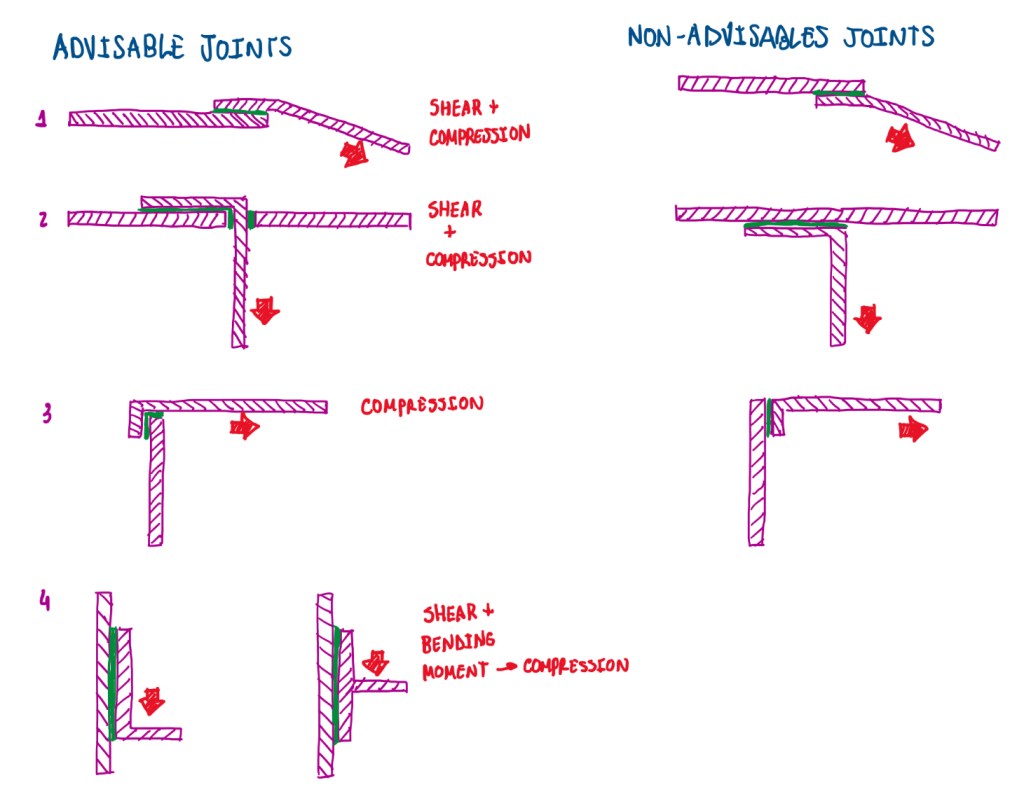

Regarding the second rule of the adhesive joints, which is basically the reduction of the stresses normal to the joint, there are some specific methods for that. The objective is to left the adhesive work as much as possible in shear. In other words, perpendicular joining must be avoided as much as possible. Usually, any kind of shear loading geometry can be used. In addition, they can be used together with perpendicular joints, in order to reinforce the joining capability. Although perpendicular junctions are pretty much dangerous, this is considering tensile stresses, there are cases which the adhesive is in vertical surfaces, but the loads are compressive ones.

There are adhesives that compressive stresses can be combined with shear ones. For instance, the combinations of shear and compression loads and shear and tension loads, respectively. A compressive loading does not damage an adhesive joint. For this reason, it is possible to mix compression to shear loading without reducing the properties of the junction. In the case that, the adhesive is being loaded totally in compression, it is essentially used to keep those two pieces together. It is stressed under compression, which means that it may last to any load. In the fourth example, the load application point generates a bending moment, which causes a local compression into the adhesive joint. In the not favourable case, it causes tension, which must be avoided.

References

- Adams, R.D. Comyn, J.W.C. Wake, Structural Adhesive Joints in Engineering. Edition 2, Chapman & Hall, 1997;

- MIL-HDBK-17-3F, Volume 3, Department of Defence (DoD) USA, 2002;

- Accessed: 06/03/24. Online at:https://www.iqsdirectory.com/articles/metal-etching/acid-etching.html