Technically, Formula 1 has always represented the top of automotive engineering, although many concepts that are used there migrate to civilian use after a few years, the curiosity of enthusiasts about how these cars work is enormous. And one of the systems that generates a lot of discussion on forums is the f1’s suspension system. More precisely the Push Rod and Pull Rod suspension systems, and today we will talk about how these efficient suspension configurations work.

Double Wishbone Suspension

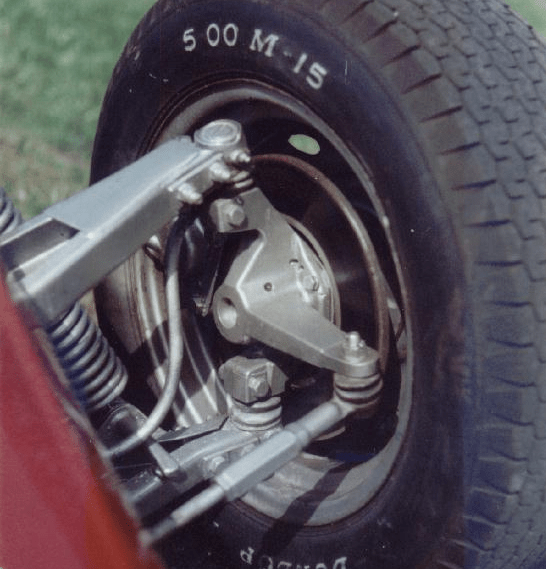

Before starting to go into the details of Push Rod and Pull Rod suspension, it is important to know that F1 cars use the Double Wishbone suspension system, so the Push Rod and Pull Rod configuration is a subtype of this suspension. . Therefore, it is important to also check how the Double Wishbone suspension works. Known in Brazil as Double A or Overlapping Arms, this suspension concept, as the name suggests, is characterized by having two suspension arms (wishbones in English), one upper and one lower. These arms can be A or L shaped, and have their ends connected to the chassis and the steering knuckle, bushings and pivots respectively intermediate this connection. During a curve, the wheel on the inside of the curve tends to increase camber, losing contact area with the ground. To reduce this phenomenon, the arms have different sizes, with the upper one being shorter than the lower one, which causes the wheel to have negative camber. It is a type of suspension widely used in high-performance cars as it combines ease of maintenance and great freedom to adjust various parameters of the suspension geometry. More details about this concept can be seen in the specific article. Shock absorbers and springs are arranged concentrically and inclined between the two arms, however, different ways of accommodating shock absorbers and springs have emerged in racing cars that use this suspension concept, and it is in this context that Pull Rod and Push Rod Suspensions come into play.

Push Rod and Pull Rod suspension

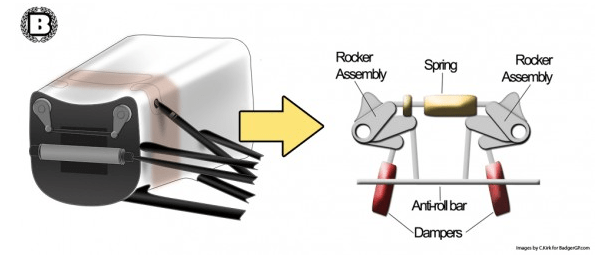

This Double Wishbone suspension configuration is characterized by taking up less space in the vehicle, a more compact and lighter package translates into better handling of the car. In Push and Pull Rod suspensions, their visible difference to conventional suspension is to remove shock absorbers and springs from the vicinity of the steering knuckle, and bring them into the vehicle chassis. This reduces unsprung mass, therefore reducing demands on the steering and suspension systems, and of course, on the driver himself. Its components are:

- Springs (torsion)/Springs;

- Shock absorbers/Dampers;

- Rockers/Rockers;

- Third spring/Inerter or Third Spring;

- Stabilizer bars or Anti-torsion/Anti-roll Bars;

- Drive rod/Pull Rod, Push Rod or simply Rod.

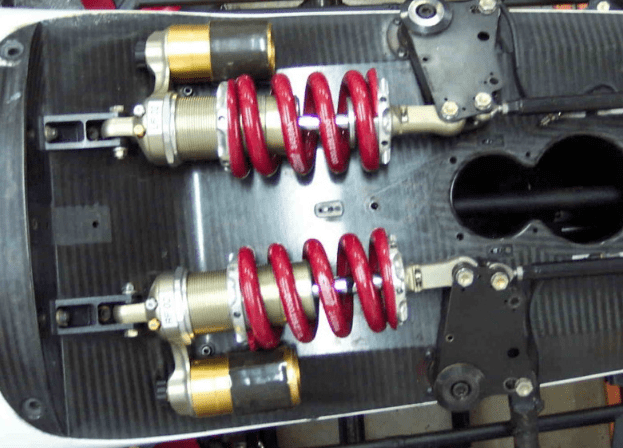

Concentric helical springs with shock absorbers, anti-torsion bars, and torsion springs, shock absorbers, rockers, the so-called third spring (Inerter) and anti-torsion bars enter the scene, all within the chassis. . Only the drive shaft (Rod) and the suspension arms can be seen, considering that the car is a single-seater (open wheels). It is important to highlight that there are pull and push rod suspensions with different combinations of components.

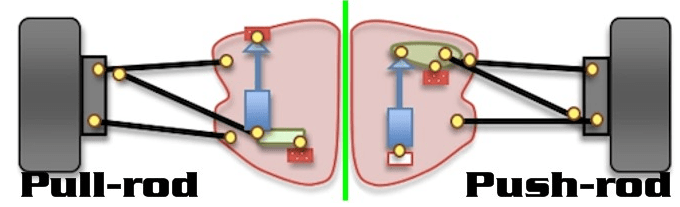

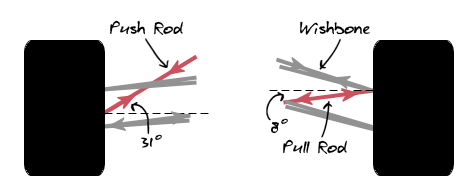

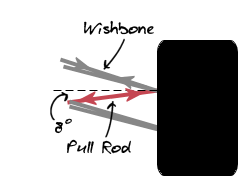

When the drive rod is fixed to the outer end of the lower suspension arm and the rocker arm in an upper position, the suspension is called Push Rod, as the rod pushes the rocker arm, which drives all other suspension components. Similarly, when the drive rod is installed at the outer end of the upper suspension arm, facing the same rocker arm, but in a lower position, the suspension is called Pull Rod, as the drive rod pulls the rocker arm, and this, when moving, activates all other components of the system.

It is so called because the rod (in this case called push-rod) pushes the suspension rocker (Rocker), the rocker in turn is connected to the shock absorbers, springs and anti-roll bars. When the car passes over a bump, the suspension moves upwards, the rod pushes the rocker, connected to the rocker are the springs (which in this case are torsion bars), when the rocker rotates, the bar rotates with it. twists generating a spring effect. The rocker arm also activates the shock absorbers and the so-called third spring (inerter), the latter is a shock absorber that prevents the car from being thrown upwards when passing over strong undulations and curbs, and the shock absorbers play their role in controlling the movements of the vehicle. suspension, preventing it from reaching the end of its course.

The advantage of this configuration is the fact that it is more resistant to the stresses suffered by the car. When the wheel moves upward, the rod exerts a force on the rocker, which also exerts a reaction force on the rod. This way the forces cancel each other out and the system wears out less. As a result, the material used to manufacture the rods and wishbones can be less robust, resulting in an excellent combination of lower cost and lower mass. The drive rods can be thinner, which puts less stress on the vehicle’s aerodynamics in that location, which otherwise could impair airflow to the rear spoiler. On the other hand, the position of the components is higher, damaging the car’s CoG, and depending on the vehicle’s design, this can seriously compromise the car’s performance on winding sections and curves.

Push rod suspension

It is so called because the rod (in this case called push-rod) pushes the suspension rocker (Rocker), the rocker in turn is connected to the shock absorbers, springs and anti-roll bars. When the car passes over a bump, the suspension moves upwards, the rod pushes the rocker, connected to the rocker are the springs (which in this case are torsion bars), when the rocker rotates, the bar rotates with it. twists generating a spring effect. The rocker arm also activates the shock absorbers and the so-called third spring (inerter), the latter is a shock absorber that prevents the car from being thrown upwards when passing over strong undulations and curbs, and the shock absorbers play their role in controlling the movements of the vehicle. suspension, preventing it from reaching the end of its course.

The advantage of this configuration is the fact that it is more resistant to the stresses suffered by the car. When the wheel moves upward, the rod exerts a force on the rocker, which also exerts a reaction force on the rod. This way the forces cancel each other out and the system wears out less. As a result, the material used to manufacture the rods and wishbones can be less robust, resulting in an excellent combination of lower cost and lower mass. The drive rods can be thinner, which puts less stress on the vehicle’s aerodynamics in that location, which otherwise could impair airflow to the rear spoiler. On the other hand, the position of the components is higher, damaging the car’s CoG, and depending on the vehicle’s design, this can seriously compromise the car’s performance on winding sections and curves.

Pull Rod Suspension

The Pull-Rod configuration works in a similar way, in which the rod (pull-rod or just rod) activates the rocker by pushing it (push), and then the other suspension components are activated. When pushed, the rocker rotates, activating springs, shock absorbers and the inerter, but with the difference that these components are located in the lower part of the chassis.

The lower position of the components improves the vehicle’s CoG, and therefore handling. However, this configuration generates greater efforts on the upper arm, requiring more robust rods, and in this case, robustness means a thicker rod. This difference ends up harming the air flow that passes through the suspension, as a thicker rod has an even greater influence on the path that the air will take after crossing it, compromising the downforce a little, in addition to being in the lowest part. of the chassis, access for maintenance, replacement and repairs is somewhat compromised, as access to components can be obstructed; in the case of the rear suspension, the gearbox can complicate the lives of mechanics.

Differences between pull rod and push rod

Both configurations are compact solutions and have the same level of performance, their differences are how much they interfere with the vehicle’s aerodynamics, component mounting position and the reaction forces to which suspension rods and arms are exposed. The mounting position of the components can affect the repairability of the vehicle. In general, vehicles with pull-rod suspension tend to make suspension maintenance more complicated, as the components are located at the bottom of the chassis and can be obstructed, thus Access would have to be from underneath the vehicle, unlike push-rod suspension, which has components mounted in a higher position. However, this is not a rule, as there are creative pull-rod suspension solutions that are less difficult to repair and maintain. In addition to maintenance, the position of the components also affects the air flow that passes through the car, depending on the type of suspension, the rods can be thinner or thicker and more robust, and interfere too much with the flow that passes through the car, disturbing the air that should be reaching the airfoils, you no longer gain a little downforce. The durability of the set is another important factor, both configurations (pull and push rod) have problems with the durability of rods and suspension arms. This is observed due to the reaction force to which the components are exposed. In pull rod configuration, the suspension has a great stress on the outer end of the upper suspension arm, as the rod is connected to it and to the rocker arm. The spring reaction force returns through the rod and goes towards the upper arm, and ends up adding to the chassis reaction force, which passes through the upper suspension arm itself, which is fixed to the chassis.

Unlike the pull-rod suspension, the push-rod suspension manages, with an arrangement opposite to that of the pull-rod, to nullify or slightly reduce the stress on arms and rods. Basically, the reaction force of the springs on the rods goes towards the outer end of the lower suspension arm, and is canceled out by the force that the wheel exerts on the arm, generating considerably less effort on both components. As a result, a less robust rod can be used, lighter and with less interference with the vehicle’s aerodynamics. It may seem that the push-rod suspension is more resistant, as it manages to nullify part of the forces that act on its components, however it suffers from a major problem when the vehicle passes over irregularities, more specifically those that cause the bump movement (compression). ) of the suspension, the buckling of the rod that cannot withstand the enormous load imposed on it in the upward movement of the suspension. This problem can also be observed in the pull-rod, but by obtaining an inverted arrangement of parts, the rod ends up suffering this load when the suspension moves downwards, and downward movements are not as critical as upward movements, ultimately ending up not having much influence on operation. What can be concluded from these two successful suspension configurations is that they both meet very well the proposal of a robust and compact package for high-performance racing cars, not only in F1, but in various single-seaters and open wheels. The definition of which concept to apply to the car will depend on which regulations or trends the cars must follow.

References

- This articles was originally published in Carros Infoco Website.