In racing cars engineering there is a great concern regarding when the laminate will fail and how they reacts to an impact. This situation is very common in motorsports since race cars are exposed, to shanks, rubbing, debris and crashes. The main objective is to protect the driver against the impact, thus the monocoque must not deform and driver must be fit. However, there are components that must deform in order to absorb the impact energy and reduce its portion that goes to the monocoque. Hence, it is necessary a deep knowledge of the physics of impacts and how composite materials deal with them. This article develops a summary of the main points regarding impact and crash for composite materials.

Impacts

Them terms impact and crash are often mentioned in wrong way, as they synonyms. Actually, they look similar, but they have a distinct definition. An impact is defined as a hit, a collision between at least two bodies that does not cause a complete or local failure of them. In addition, an impact does not means the complete stop of the body. Usually, impacts leave damages or even perforations, but it does not cause the collapse of the structure. On the other hand, a crash causes an immediate collapse of the structure, but always involves the complete stop of the body. This means that, the body or structure absorbed the energy of the crash while it is being deformed. Crash box and the front end of road and race cars are structures developed with this concept. These are called, impact accumulators or crash absorbers, which are structures sacrificed in order to preserve the passengers and racer drivers.

Types

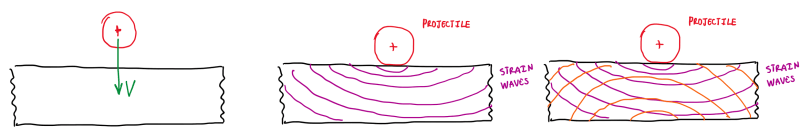

Basically, there are two kinds of impacts, the low and the high velocity ones. However, it is not easy to develop a threshold value that classify an impact as low or high speed velocity. The reason is that, the impact type depends on speed, size, stiffness and boundary conditions. Normally, the higher the stiffness, the higher the impact speed. Regarding, composite materials, more specially the carbon fiber epoxies, the speed range from 10 to 100 m/s is considered a transition zone between low and high speed impacts. However, a general definition states that, an impact can be defined by comparing the duration time of it with the propagation time of the strain waves into the component

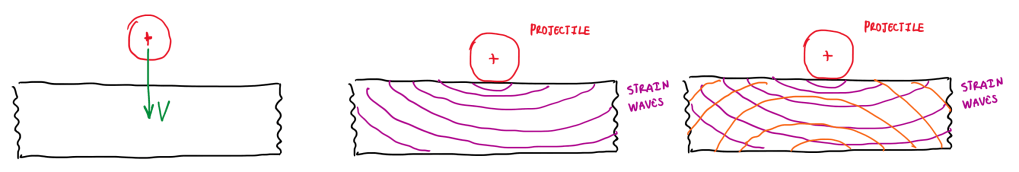

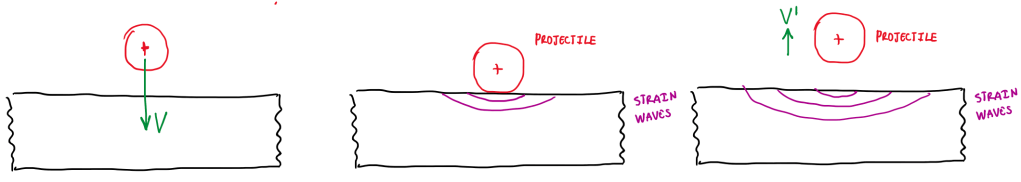

Considering a plate which is shot by a projectile. When the structure is hit, strain waves are generated at the impact local. These propagate through the material thickness until the other surface. At this point, the strain wave are reflected back to the previous surface. Hence, it is possible to notice that, there two important times, the impact and the propagation ones. The first is the time at which the projectile is in contact with the plate. The propagation time means the time at which the strain propagated and reflected back to the impact local.

Low speed impacts

If the the impact time is higher than the propagation one, this means that the strain waves are already propagated throughout the entire plate thickness and returned to the original surface. This is the low speed impact. Nevertheless, the most important aspect of the low speed impact is that, the strain can be assumed fairly constant. In other words, it is just determined by the forces exchanged between the plate and the projectile. Hence, this has an effect which is very similar to a static load applied to the plate.

High speed impact

Regarding high velocity impacts, it is possible to consider the same plate and projectile example. In this case, the projectile hits the plate and bounces back before the strain waves even reach the other surface. Hence, there is a region which is more stressed, a local stress. The strain waves only affected nearby regions, while the remaining ones are roughly damaged. In high velocity impacts, the stress and strain during the event is non-linear. The propagation time, in this case, is higher than the impact time.

Automotive impacts

With respect to the racing field, the low impact velocity is usually assumed. The reason is that, the common impacts are due to shanks and debris and the velocity of the cars are about 90 m/s. It is not usual to have a high speed impact in this context. Actually, this is more the case for balistic armours. In this one, Kevlar is an usual material, because it is capable to deal with the high stress and strain at the local of the impact. This material is very useful to maximize the energy absorption and slow down a projectile. Kevlar is an aramid fiber and it is also use for racing car monocoques. They are used as lateral protection against penetration.

Fiber breakage

The damage occurs by many different ways, but it is important to verify if the fiber breaks or not after the impact. Actually, this can indicates the energy of the impact. In the case of fiber breakage after the impact, this can be characterized as a high energy impact, because it is higher than the energy that the material can sustain. For cases like that, the use of materials with high strain at failure is advisable. In terms of elective fibers, the best ones are glass and, mainly, aramid. These are better than carbon fiber, because this one has low strain at failure. The impact in which there is no fiber breakage is classified as low energy one. The energy of the impact is lower than the one that the material can afford. However, this is not less important then the high energy ones and does not means that there is no damage. Actually, casas like that can hide a delamination since it is a sort of damage that occurs beneath the surface. Hence, it is very difficult to know if the material is damaged or not. For cases of low energy impact, it is more important a material with a high ply interface strength. In real environments, it is very difficult to define if the impact was from high or low energy, because there are more factors being part of the process. For example, the lay-up of components, the overall shape and manufacturing aspects also comes into play when impacts occur. Hence, most of the impact evaluations are performed at FEM simulations.

Test procedure

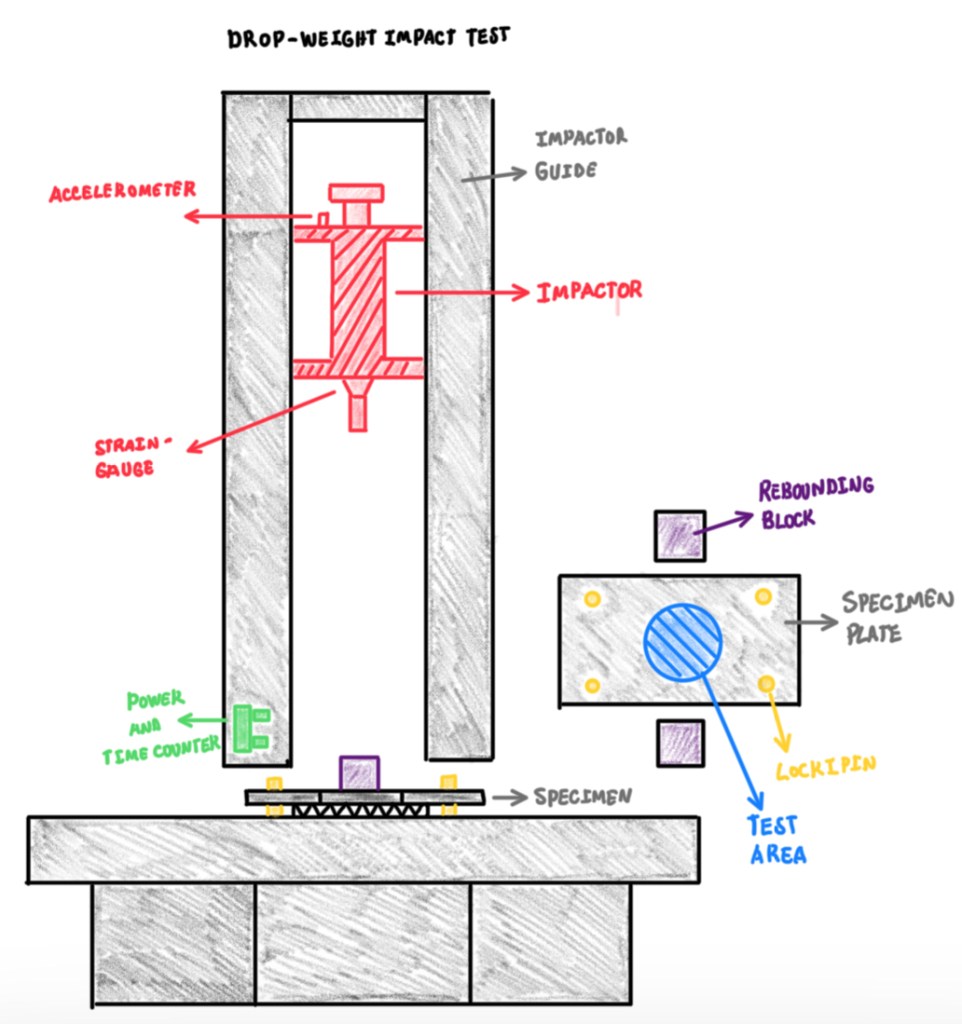

The test procedure for impact strength and damage for composite materials follows the ASTM D7136 standards. It is a basic and well known drop weight impact test. Then it is based in an impactor that is left to fall from a pre-determined height. This means that, the impactor has some potential energy stored. Once it falls, this begins to be converted into kinetic energy. Then, the specimen will absorb this energy. It is a plate, fixed by locking pins at its four corners. The impactor will hit the plate just at the center. It is fitted with an accelerometer, load cells and strain-gauges, in order to register the deceleration when it reaches the plate. Hence, it is possible to integrate the deceleration to obtain the velocity and the displacement during the impact. Another device is a time counter. It defines a countdown to trigger the data acquisition. The reason is that, the impactor occurs in milliseconds and the time for the impactor hits the plate is in the order of magnitude of seconds. Hence, if the acquisition is active since the test beginning, the amount of samples would be very high since it is set a frequency of tenths of kilohertz. This means that, just 1 second is capable to generate about 20,000 samples, which just few hundreds are really the test itself. To avoid that, the time counter is set to only activate when the impactor is close to the hit point. Once there is the possibility to the impactor bounce back, the test machine is fitted with anti-rebounding block. This device also account leverages on the impactor. The objective is to avoid the bounce and a second hit from the impactor. The reason is that, the system will register the second damage, which impairs the data results.

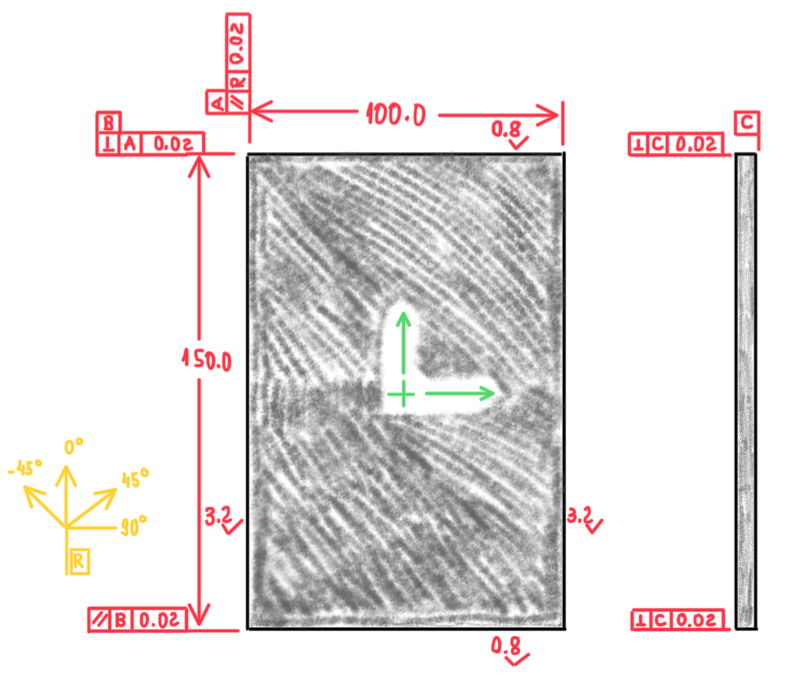

Specimen

The specimen is a rectangular plate made from composite materials and with dimensions specified by the standards. These also specify the surface finishing of the specimens. The lay-up vary according to the ply thickness of the unidirectional tape of woven fabric. The first one has a lay-up of 45°/0°/-45°/90° plies. The woven fabric is a quasi-isotropic lay-up, it is composed by two plies with anti-symmetric orientations, which 45°/-45° 0°/90°. These are repeated several times in order to form a symmetric lay-up. It is possible to develop different lay-ups or specific for one application, but these are not supported by the standards. Usually, these are in-house lay-ups and have its own standards.

Test results

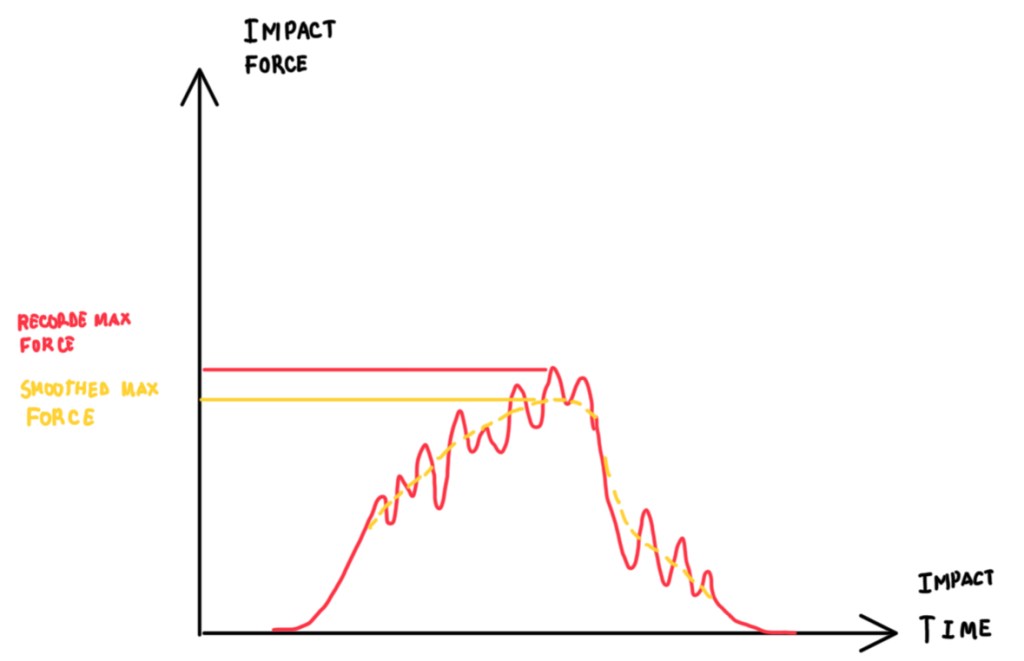

The test results are plotted in a graph that indicates the impact time and force. This is obtained through the data from accelerometers, thus the impactor mass times the acceleration delivers the force. Integrating the acceleration allows to plot another graph, with the displacement with respect to the force. It is common to observe some oscillations in those graphs. These occur due to the impact, that also causes vibrations on the impactor which are transmitted to the entire system. The response of the impactor excites the plate and this is registered by the data acquisition system. Hence, it is necessary some data filtering in order to smooth the curve oscillations. These are called ringing and are caused by the impactor resonance, which is registered by the load cells.

Possible damages

In terms of the specimen condition after the test, there are several types of damages, the most common, and observable, are the indentation, depression, splits, cracks and fiber breakage. Some cases of delamination can be visible. However, these are rather easy to identify, which is not the case for delamination and some splits and cracks. These are defined as internal damage since can only be spotted by non-destructive inspections as ultrasound and xerography. This is a process which an optimal monitoring of the surface is performed previously and after the test. The software creates a pattern of dots on the surface of the test. Then, after the test, those dots are again verified. It compares the undamaged and damaged surface dots. Their displacements allow to calculate the strain, thus the stress. Sometimes the damage generated is a delamination between the first and the second plies. In this case, it is possible for the software detects the damage, because this delamination causes distortions on the strain field. However, if the delamination is too beneath, then the ultrasound technique should be used. The larger is the crack, the higher is the impactor penetration.

References

- MIL-HDBK-17-3F, Volume 3, Department of Defence USA (DoD), 2002;

- Busco, A. Comportamento all’impatto dei materiali compositi. Tese di dottorato, Università di Napoli “Federico II”, 2007;

- Borelli, R. Sviluppo di procedure numeriche per la simulazione del danno in strutture in composito. Tese di dottorato, Università di Napoli “Federico II”, 2011.