The battery of an electric vehicle EV is the main component of this kind of car. Even though it is its source of power, it works completely different from fuels. Actually, a battery is composed by hundreds or thousands of cells. These are the smallest energy source of the battery. Hence, a proper denomination, characterization and testing, were defined by the electric technical commission IEC. It states that the most basic element, the cell, is defined as one anode, separator, and cathode. Actually, the configuration of a stack cell is anode, cathode and electrolyte packed together. For multiple cells arranged, IEC named it as a module. Nevertheless, this is conventionally called a cell. The difference between these two cell definitions is the electro-magnetic force. This means that a cell is the one with a single voltage possible. Hence, the stacking configuration increases the current flow Aᐧh. Hence, an increased internal active surface. For that, it necessary a series of cells in parallel. However, by convention, it is just named, cell. A module is a group of physically separated cells, which can be cylindrical or prismatic. This article provides an overview of the cells used in automotive application discussing its types, configurations and quality aspects.

Cell classification

There are three classes of cells, the primary, secondary and reserve. The first one is the usual of ordinary batteries. They are charged, then discharged and disposed of. The secondary is a sort of multi-use cell and can be recharged. The third category is reserve cells, which are widely used in military applications. They can be stored for a very long time. This makes them suitable for applications that require safety, like satellites and missiles. A battery with those cells can last about 20-25 years, which makes them very expensive. For this reason, it is unlikely to be fitted in cars. However, for automotive applications, cells are classified to shapes and arrangements.

Cell shape

The cell shapes are basically prismatic and cylindrical. The cylindrical cell is a very simple concept. It is composed of a metallic, cylindrical, and bonded container. This container is connected to the anode inside. The upper part is insulated and connected to the cathode. Additionally, there is a venting valve inside. This is very solid, consistent and autonomous with respect to its mechanical operation. It allows storing a lot of energy inside. However, its size is a limitation. This makes it difficult to create a customized battery pack. These aspects justify the investment of car companies on different types of cell shapes.

The prismatic cells have two common categories, the blade and pouch ones. Actually, the first is a subcategory of pouch cells. These were developed by BYD about 2023. Basically, pouch cells a stack of electrodes inserted in an aluminum bag. This is composed of five layers with the following configuration: polyethylene, polypropylene, aluminum laminated foil, polypropylene and polyethylene. The use of polypropylene between aluminum and polyethylene is to avoid bound creation, which would occur if polyethylene and aluminum were together. Hence, the polypropylene is a sort of primer for the aluminum. An important aspect for these kinds of cells is that the electrodes must be perfectly parallel in order to perform quite well. In addition, when lithium is inserted in the graphite, the lithium carbonate increases the volume. This compound has a yellow colored aspect and increases the volume by the double of the original lithium amount. The result is a mechanical stress on the cell, which is commonly referred to by cell breathing. This is a phenomenon that changes the shape of the pouch cell, thus the distance from the electrons. In other words, a long path of the material to move through that, in terms of path, the electrons will face a higher resistance. Hence, the contact between lithium and graphite increases the internal resistance of the cell.

Therefore, a standard procedure when using pouch cells batteries is to mount them under external pressure. Prismatic cells form a rigid container. They can apply pressure on the inside cells. This is why the containers are substituted. Even though it has a prismatic shape, it is possible to use a folded ellipsoidal structure of electrons. This configuration is cheaper with respect to cost production. This idea is based on folding and pressing two metals. This allows us to take advantage of the metal’s spring effect. This is the reason behind having cheaper forming of internal components, it is necessary an external rigid structure. The objective is to make pressure while the electrodes are kept parallel. Therefore, if the pouch cell is selected for an electric vehicle battery, it is necessary an external pressure source. In summary, solutions that compress the structure. Actually, this pressure is a critical parameter, but its value is not so high. The problem is that this pressure threshold is not mentioned in technical sheets of cells. It should be formally requested from the supplier.

Ingegneria Energetica e Nucleare, Dicembre, 2021.

Another important aspect with respect to the pressure in batteries is its relation with charging and discharging processes. The pressure from inside to outside cell structure varies according to the process occurring on the battery. Hence, it increases depending on the state-of-charge SoC. For instance, a battery with 100% SoC means an amount of lithium carbide in the cell. Then, there is a pressure difference inside to outside and it affects the cell performance. Subsequently, it is possible to understand that the performance of the cell depends on several different parameters. Those must be taken under consideration, especially when using pouch cells. One of those parameters is the tab design. If there are tabs on the same side for exactly the same cells in terms of active material and the same is done in the opposite, the thermal behavior of the cell is improved. Additionally, temperature is a parameter that affects the cell performance in terms of electricity. Those aspects regarding cells suggest that batteries for electric vehicles are all about balance on these aspects. Therefore, a cell must never be selected considering just one parameter. It is necessary to conduct a deep analysis of the cell structure and the application.

Arrangement

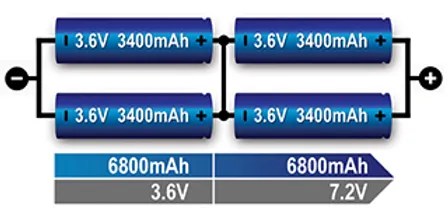

There are two basic concepts with respect to cell arrange, series and parallel. When cells are arranged in series, the voltage increases for the same current flow. Actually, this configuration does not increase the surface of electrodes, instead only the electrode amount is multiplied.

In the parallel arrangement, the voltage is not increased, but the active surface that absorbs electrons increases. Hence, the voltage is the same, while the current flow increases. However, it is possible to have both characteristics by combining both arrangements, this is the mixed cell arrangement. The objective is to obtain the desired voltage and current flow for the application. An important aspect for any cell or battery pack is the working voltage and current change during the discharging process.

Additionally, compared with the wet cell batteries, this variation is much higher due to the water polarity and the internal resistance. Hence, with a lithium-ion battery powered car, the efficiency regarding power and current is more stable since the discharging curve in function of the voltage is more linear. Hence, using lithium-ion batteries, as a source of 12V power with respect to lead-acid ones, it is possible to increase by 20% the range in terms of consumption. The reason is that the lithium-ion battery completely absorbs the energy produced by the generation, while lead-acid batteries have an initial re-charging efficiency of 50%. This value decreases according to charging-discharging cycles. As a result, the alternator works significantly less, which allows for an ICE powered car a significant mileage improvement.

Cell quality

Quality is a very important variable when designing a battery pack. Hence, there two important indicators of quality, performance and temperature. It is strongly necessary to select almost the equivalent cells in terms of performances in series and/or parallel. The reason is that any cell with a different variation in terms of performance causes an accelerated aging of the entire battery pack. Regarding the temperature, it is extremely important to ensure its uniformity in the battery pack. The reason is that the cell performance varies with the temperature. If this exhibits exaggerated variations, it causes an accelerated aging of the battery pack. An example of this issue occurred in La Ferrari, which was equipped with a non thermally balanced battery pack. Consequently, more than 300 battery packs of 499 had been changed. This case is so representative since this kind of car just runs a few miles. Hence the magnitude of this issue in a mass produced electric car would be catastrophic. Therefore, the quality of the cell manufacturer, in order to provide the smallest standard deviation, should be the highest possible.

Thermal balance

Once the simulations are done, the selected cells are analyzed by the chemistry lab to assess the performances, the next step is the battery pack design. For that, it is necessary the production tolerance range and thermal balance. Even though considering a cell in series arranged with an ensured thermal balance, it is still possible to have the wrong voltage. The reason is that, the current flow through the media and connections cell to cell has different resistances and they reduce the voltage. This parameter is the electro-magnetic force that is driven by material inside. Even providing a thermal balance, they can be unbalanced according to the position on the row. This means that it is necessary to have a strategy to keep as much as possible the balance of cell performances. Assembling cylindrical modules is somehow rigid structure, the cylindrical cells are rigid in terms of structure. Hence, there is no window for creativity in designing the battery pack composed of cylindrical cells. Pouch cells are more flexible, since they are stacked, an external pressure is necessary. This must be even along the series of cells. This is the main challenge when designing this type of battery pack. It is necessary to account for the pressure across the module. The prismatic cells are easier to assemble and provide a rigid structure. However, it is the configuration that has issues with their cooling.

References

- This article was based on the lecture notes written by the author during the Vehicle Components Lectures of the Advanced Automotive Engineering Master Degree course at Università di Modena e Reggio Emilia;

- Nick. (n.d.). Cell-to-pack batteries – E-Mobility Engineering. E-Mobility Engineering. https://www.emobility-engineering.com/cell-to-pack-batteries/;

- Plus, A. H. (2021, July 8). การเชื่อมต่อเซลล์แบตเตอรี่แบบอนุกรมและแบบขนาน (Series and parallel battery configurations). AEC. Retrieved October 19, 24 C.E., from https://www.aec-engineer.com/post/series-and-parallel-battery-configurations;

- Powerbank20. (2022, August 13). Qual è la capacità reale di un Power bank? PowerBank20. Retrieved October 19, 2024, from https://powerbank20.com/it/capacita-reale-vs-nominale/;

- Administrator. (2024, April 26). Learn how to arrange batteries to increase voltage or gain higher capacity – HiMAX. Himax. Retrieved October 20, 2024, from https://himaxelectronics.com/learn-how-to-arrange-batteries-to-increase-voltage-or-gain-higher-capacity/;

- Mazzeo, Francesco. Methodological development of a digital twin for Li-ion cells simulation: An experimental and numerical assessment. Politecnico di Torino Ingegneria Energetica e Nucleare, Dicembre, 2021.