The sand casting is the most used casting process and also the older between it. It is part of the group of expendable molds process. It stimates that around 15 milion tons of metal are cast each year by this process. It consists of placing a pattern that have shape of the desired part in a sand to make an imprint. Then a gating system introduced to permit the molten metal entrance in the mold. The pattern is removed and the mold cavity is filled with molten metal. The metal is left to cool until its solidification. In the sand mode is broken away and removed.

Sand

The sand casting use this particular material to build molds and cores due to its high melting point and thermal stability. In general, there are two types of sands, the natural and the synthetic. The first is mixture of sand (SiO2), clay and moisture. The synthetic is sand and synthetic binders cured thermally or chemically. There three main characteristics required in a sand for this process, grain size, permeability and collapsibility. The grain size directly inflicts the roughness of the part surface. As smaller the grain size, smoother is the surface of the part produced. However, the lower grain size also expose the process to a reduced permeability. In other words, the passage of gases and fluids through the sand pores, locking then into the cope and drag. In addition, the sand should provide molds with collapsibility, that is the allowance of the casting shrinkage during the cooling process that can result in casting hot tearing and cracking [1].

Automotive applications

- Engine blocks;

- Engine manifolds;

- Cylinder heads;

- Transmission cases.

Process

The process begins (Figure above) with the part drawing development. From this the core print will be manufactured to be pressed against the core and the drag pattern plates. In this last one a gate is made. These pattern are placed in two sand boxes to make an imprint. Hence the core boxes are done. After that a core with a shape similar to the real part is made in halves and them pasted together and placed in the core boxes. This core is important to provide the hollow of component being casted. The cope box receive the risers, sprue and flask, components that will guide the molten metal and the gases that are expeled by the process. Hence the drag box also is assembled with flask. After that cope and drag are done and ready to be assembled together with the core pattern inside. The mouten metal is poured through the risers and the gate in the drag permits the molten metal to reach the molds and the core pattern. The mold will shape de molten metal into part shape and the core pattern will provide hollow section. The cooling period is stablished, the molten metal solidifies and the cope and drag are disassembled and the part is removed.

Atributes

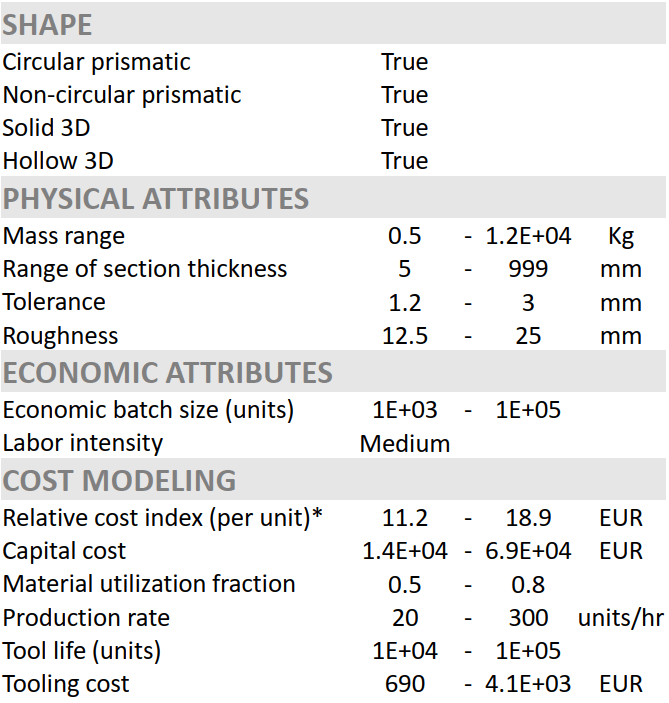

As can be note, the sand casting process has a very little limitation on shape. The process has particular advantages for complicated castings with differing section sizes. Bosses, undercuts, inserts and hollow sections are all practical. In therms of physical attributes this process is capable to provide light, medium and heavy duty parts (from 0.5 kg to 1.2E+4 kg). However, relative to accuracy and dimensional tolerance, the sand casting deliver parts with great thickness (5 to 999 mm) and roughness (12.5 to 25 mm). Which means that these parts require a post-processing as machining to adequate the surfaces to the dimensional tolerance. Another good attribute of the sand casting is the batch size, that ranges from 1.0E+3 to 1.0E+5. The labour intensity is rated medium, because even furnaces and casting are very physically hostile places, this process became more and more automated reduncing human effort. In terms of cost, a casting structure is expensive, with a capital cost of 1.4E+4 to 6.9E+4 Euros, but its is amortized over the production. The cost index, or cost per unit, varies between 11.2 and 18.9 euros and this one of the best attributes of this process, relatively affordable parts produced. Relative to the sand casting maintenance, tool life and tooling cost are rated. These measures the period that sand casting can produce parts without a break to tooling. In fact the tool life may be the batch size, although the tooling cost is relativelly higher, 690 to 4.1E+3 euros. The process is suitable for the majority of aluminum and copper-base alloys, steels and cast irons. Cast irons are the most commonly used material. The process is not used for refractory or reactive metals [2]. Another attributes is the draft angle, 1-5 deg, the machining allowance, 1.5-6 mm, the minimum section of 3 mm for light alloys and 6 mm for ferrous alloys.

Reference

- Serope Kalpakjian, Steven Schmid – Manufacturing, Engineering and Technology-pearson (2009);

- Granta CES 2019.

I found your detailed explanation of the sand casting process to be both thorough and insightful. As someone involved in foundation work, I was particularly interested in your discussion of the advantages of sand casting for creating large, complex parts. The ability to reuse sand and the relatively low cost of the process makes it an appealing choice for various construction-related components, especially when considering foundation elements like concrete forms or metal reinforcements. Your breakdown of the material properties and the different types of sands used also provided a great deal of practical information.

I’m curious, in the context of foundation work, how would you compare the use of sand casting for creating custom metal reinforcement brackets versus other manufacturing methods, such as die casting or investment casting? Are there specific factors like load-bearing capacity or environmental conditions that would make one process more suitable than the others in foundation applications?

https://www.vegasfoundations.com/

LikeLike